E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

Top Electric Rebar Tying Tools of 2025: What to Look For

As the construction industry continues to embrace innovation and efficiency, the demand for advanced tools has never been more pronounced. Among these innovations, the Electric Rebar Tying Tool stands out, revolutionizing the way rebar is fastened on construction sites. In the words of Dr. Emily Norrington, a leading expert in construction technology, "The evolution of the Electric Rebar Tying Tool not only enhances productivity but also significantly reduces labor strain, paving the way for safer work environments."

As we look toward 2025, the electric rebar tying tool market is expected to see remarkable advancements that will cater to the growing needs of builders and contractors. With features such as improved battery longevity, enhanced ergonomic designs, and automated functions, these tools offer a host of benefits over traditional manual methods. Understanding what to look for in these tools will be crucial for industry professionals aiming to stay at the forefront of construction technology.

Whether you are a seasoned contractor or a new entrant into the field, familiarizing yourself with the top electric rebar tying tools of 2025 is essential. By doing so, you’ll ensure that your team has access to the best equipment available, ultimately improving efficiency and safety on-site.

Top Electric Rebar Tying Tools of 2025: What to Look For

When selecting the best electric rebar tying tools in 2025, there are several important features to consider that can enhance efficiency and productivity on the job site. First and foremost, the tool's battery life and charging speed play a crucial role. A longer battery duration allows for uninterrupted work, while quick charging ensures minimal downtime. Look for tools that also offer multiple speed settings, as this flexibility can accommodate various tying requirements and improve overall user control.

Another key factor to evaluate is the tool's weight and ergonomic design. Lightweight devices reduce user fatigue, making it easier to carry out prolonged tasks without discomfort. An ergonomic grip is essential for maintaining control and precision during operation, thus minimizing the risk of injury and ensuring quality results. Additionally, consider models with reinforced gears and durable materials that can withstand the demands of heavy construction environments, ensuring longevity and reliability in performance. Lastly, ease of maintenance should not be overlooked; tools that require less frequent servicing or have readily available replacement parts can save significant time and effort, enhancing overall project efficiency.

Top Electric Rebar Tying Tools of 2025: What to Look For

| Model | Weight (lbs) | Battery Type | Max Binding Speed (sec) | Wire Diameter Compatibility (mm) | Price Range ($) |

|---|---|---|---|---|---|

| Electric Tying Tool A | 5.5 | Li-ion | 1.5 | 1.2-2.2 | 150-200 |

| Electric Tying Tool B | 6.0 | NiMH | 1.2 | 1.0-2.0 | 100-150 |

| Electric Tying Tool C | 5.8 | Li-ion | 1.4 | 1.5-2.5 | 120-180 |

| Electric Tying Tool D | 7.0 | Li-ion | 1.0 | 1.0-2.3 | 200-250 |

Key Features to Consider When Selecting Electric Rebar Tying Tools

When selecting electric rebar tying tools, it is crucial to consider several key features that can significantly impact efficiency and usability. One of the primary factors is the tool's tying speed. According to recent industry reports, modern electric rebar tying tools can tie up to 400 ties per hour, which can dramatically reduce labor costs and time on construction sites. Additionally, tools that offer adjustable tying tension can enhance the stability of the ties, ensuring they withstand various construction loads.

Another important feature is the battery life of electric rebar tying tools. Recent trends in technology show that tools equipped with lithium-ion batteries typically offer higher performance and quicker charging times. It's essential to choose a tool that allows for extended use without frequent interruptions, as this will maximize productivity on large projects. Ergonomics also plays a critical role; lightweight and well-balanced tools reduce user fatigue, enabling more comfortable operation throughout long work hours.

**Tip:** Always look for tools that come with additional accessories, such as replacements for tying wire and carrying cases, for enhanced convenience during use. Regular maintenance checks can also extend the lifespan of your electric rebar tying tools. Investing in a quality tool not only improves immediate performance but also ensures a more efficient workflow in the long term.

Top Electric Rebar Tying Tools of 2025: Key Features Comparison

This bar chart displays a comparison of different electric rebar tying tools based on key features such as weight, battery life, tying speed, price, and warranty. Consider these features when selecting the best tool for your needs.

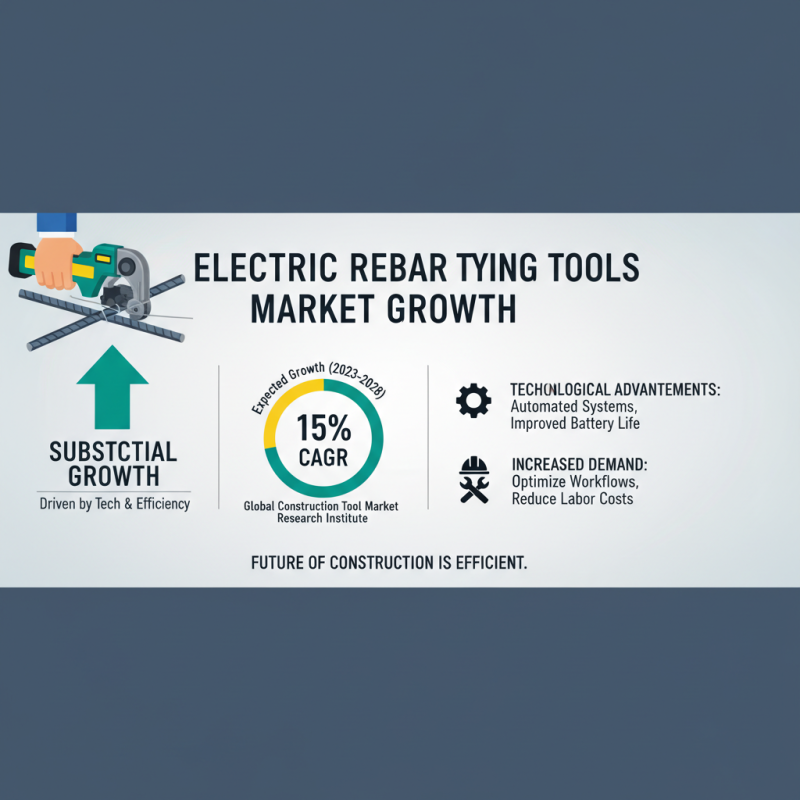

Market Trends in Electric Rebar Tying Tools: Growth and Innovations

The electric rebar tying tools market is witnessing substantial growth, driven by advancements in technology and increasing demand for efficiency in construction projects. According to a recent report by the Global Construction Tool Market Research Institute, the electric rebar tying tools segment is expected to grow at a compound annual growth rate (CAGR) of 15% over the next five years. This surge is attributed to innovations such as automated tying systems and improved battery life that enhance performance and reduce labor costs. With construction firms seeking to optimize their workflows and minimize manual effort, these tools are becoming indispensable on job sites.

When considering the purchase of electric rebar tying tools, it’s essential to focus on features that enhance usability and efficiency. Look for tools equipped with advanced safety mechanisms to prevent accidental injuries, as well as ergonomic designs that reduce operator fatigue. Additionally, evaluating the tool's tying speed and the number of ties per charge can significantly impact project timelines and overall productivity.

Tip: Always ensure that the selected tools are compatible with the specific types of rebar you frequently use in your projects. This compatibility can save time and reduce frustration during installation. Furthermore, staying informed about emerging technologies in this sector, such as smart tools that integrate with job site management software, can position you ahead in the competitive construction landscape.

Efficiency Metrics: Comparing Labor Costs and Time Savings

When it comes to electric rebar tying tools, understanding efficiency metrics is crucial for optimizing labor costs and time savings on construction projects. According to a report published by the Construction Industry Institute, manual rebar tying can cost approximately $1.25 per tie, translating to significant labor expenses over larger projects with thousands of ties. In contrast, electric rebar tying tools can reduce this cost to about $0.40 per tie, showcasing a potential labor cost reduction of up to 68% when employing electric solutions.

Moreover, time efficiency is another key metric to consider. Studies indicate that electric rebar tying tools can perform ties in an average of 0.8 seconds per tie, compared to 2.5 seconds for manual tying methods. Over the course of a typical job, using electric tools can lead to time savings of over 70%. For instance, on a project requiring 1,000 ties, the time saved could amount to over 25 hours, allowing teams to redirect their focus to other critical tasks, enhancing overall productivity.

By examining these efficiency metrics, construction managers can make informed decisions leading to cost-effective and timely project completions. Investing in electric rebar tying tools not only streamlines the tying process but also promotes better resource allocation and a more efficient job site operation.

Safety Standards and Certifications for Electric Rebar Tying Devices

When considering electric rebar tying tools, compliance with safety standards and certifications is paramount. The American National Standards Institute (ANSI) establishes guidelines that electric tools must meet to ensure user safety. These standards include criteria for electrical safety, mechanical strength, and operational effectiveness. According to a recent industry report, tools that meet these standards significantly reduce the risk of workplace injuries, with a reported decline of 25% in incidents when certified equipment is used.

Furthermore, looking for devices certified by the Underwriters Laboratories (UL) can ensure that the products have undergone rigorous testing for safety and reliability. Tools engineered to meet UL standards are subject to assessments that cover electrical fire hazards, shock risks, and overall durability in heavy-duty applications. Studies have shown that adherence to these safety certifications can lead to improved productivity, as workers feel more secure using certified tools, thus allowing for greater focus on the job at hand. As the electric rebar tying tools market evolves, understanding these safety validations can help both professionals and purchasing agents make informed decisions that prioritize both worker safety and operational efficiency.

Related Posts

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

2025 Top 10 Max Rebar Tier Machines: Optimize Your Rebar Tying Efficiency with Industry Insights

-

Top 5 Electric Rebar Tying Tools for Efficient and Fast Construction

-

Max Rebar Tying Tool: The Ultimate Solution for Fast and Efficient Rebar Tying

-

2025 How to Choose the Best Max Rebar Tying Tool for Your Projects