E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

Top 10 Portable Rebar Tying Tools You Must Consider for Your Projects?

In the world of construction, efficiency is key. A Portable Rebar Tying Tool can significantly reduce the time spent on tying rebar. This tool is essential for any serious builder. It provides the convenience of mobility and ease of use in various work sites.

Many options exist for different budgets and needs. Some tools are lightweight, making them easier to carry around. Others offer advanced features that enhance productivity. However, choosing the right tool can be overwhelming. Not all tools are created equal, and some may not perform as expected. This can lead to frustration during crucial project phases.

Quality and durability should be a priority when selecting a Portable Rebar Tying Tool. A poorly constructed tool can lead to defects in your work. Sometimes, it’s worth investing more upfront for better reliability. Reflecting on your choices is essential to avoid setbacks. A good tool can make all the difference in your construction projects.

Top 10 Portable Rebar Tying Tools for Efficient Construction Projects

When tackling construction projects, efficiency is key. Portable rebar tying tools can significantly speed up the process. These tools allow workers to easily secure rebar in place without excessive manual effort. Imagine a job site where each tie happens in a fraction of the usual time. That’s where these tools come in handy.

Choosing the right tool matters. Not every portable rebar tying tool offers the same level of performance. Some may even fall short in durability or ease of use. For instance, a tool that jams frequently can frustrate workers and slow down progress. It’s essential to test different models to see which fits your specific needs best.

Moreover, consider how each tool affects your workflow. Heavy tools can be tiring. Lighter options allow for faster movement on-site. Even the weight distribution matters; a well-balanced tool can increase precision and reduce hand fatigue. Evaluating these factors can lead to better decisions and more efficient projects. It's imperative to reflect on what features truly enhance your work process.

Key Features to Look for in Rebar Tying Tools: Speed and Durability

When selecting a portable rebar tying tool, speed and durability are crucial factors. A tool that operates quickly can save you valuable time on your projects. Look for options that allow for rapid tying without sacrificing stability. A good tool should help you finish your work faster, especially on large-scale jobs. But speed shouldn't come at the cost of quality.

Durability is equally important. A well-made tool can withstand tough job site conditions. It should be able to handle repeated use without breaking down. Many tools may promise durability but fail during long-term use. This is where user reviews can shine—consider feedback from others who have faced similar challenges.

Don’t ignore the weight of the tool. A lightweight option can reduce fatigue during extended tasks. However, it should still feel sturdy in your hands. Test various models to find the right balance between weight and performance. Sometimes, the most popular choice might not be the most suitable for your unique needs. Reflect on your requirements carefully to make an informed decision.

Top 10 Portable Rebar Tying Tools - Speed vs Durability

Comparison of Manual vs. Battery-Powered Rebar Tying Tools

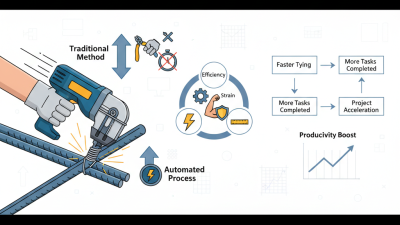

Choosing between manual and battery-powered rebar tying tools can impact your project significantly. Manual tools often offer simplicity. They require no batteries, making them lightweight and easy to use. However, they can be physically taxing, especially on large jobs. Users may find fatigue sets in quickly. This could slow down progress and affect overall efficiency.

On the other hand, battery-powered tools are designed for convenience. They make repetitive tying tasks much quicker and require less physical effort. This can lead to higher productivity in the long run. Yet, these tools can sometimes be heavy. The need to monitor battery levels can also be a concern. Transitioning to a battery-powered tool might take some adjustment. Not everyone may embrace the new tech right away. Ultimately, the choice hinges on personal preference and job requirements. Evaluate the tasks at hand. Consider how much physical strain you can endure.

Safety Considerations When Using Portable Rebar Tying Tools

When using portable rebar tying tools, safety should be the top priority. These tools can be powerful but also pose risks if not used properly. Always wear appropriate personal protective equipment, like gloves and safety goggles. Check the tool before use. Inspect for any signs of wear or damage. A faulty tool can lead to accidents.

Make sure to maintain a proper stance while tying rebar. This will help prevent injuries caused by slips or falls. Keep your fingers clear of the tying mechanism to avoid pinching. Stay aware of your surroundings, particularly other workers. Distracted or hurried actions can lead to mistakes.

Tips for effective use: Always read the instruction manual before operation. Familiarize yourself with the tool’s features. Practice on scrap rebar if you're new. It is better to spend time mastering the skill than to rush and risk injury. Lastly, store tools in a dry, secure place. Tools left unattended can cause accidents. Consider these precautions seriously for a safer work environment.

Industry Insights: The Impact of Reliable Tools on Project Timelines

Reliable tools can significantly impact project timelines in construction. According to recent industry reports, up to 30% of project delays can be attributed to inefficient tools. The right portable rebar tying tools can minimize these delays. These tools not only improve efficiency but also enhance safety on site. When workers can depend on their tools, they can focus more on their tasks.

The choice of a high-quality rebar tying tool can save time and reduce labor costs. A study found that modern tools can increase tying speed by over 50%. This is crucial in tight schedules where every minute counts. Moreover, the right tools can decrease the risk of injuries, making a safer work environment.

Tips: Always assess the ergonomics of your tools. Comfort can lead to better productivity. Make sure to train your team on proper tool usage. Effective training can prevent misuse and costly mistakes. Even the best tools require careful handling; avoid neglecting maintenance. Working with reliable tools should be a priority, but don’t overlook the importance of team training.

Related Posts

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects

-

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs

-

How to Choose the Best Max Rebar Tying Tool for Your Project

-

Top 5 Electric Rebar Tying Tools for Efficient and Fast Construction

-

Max Rebar Tying Tool: The Ultimate Solution for Fast and Efficient Rebar Tying

-

What is an Electric Rebar Tying Tool and How Does it Improve Your Efficiency