E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

Top 10 Max Rebar Tier Guns for Efficient Construction Projects

In the fast-paced world of construction, efficiency and precision are paramount. The use of advanced tools can significantly enhance productivity and quality on job sites, and one such essential tool is the Max Rebar Tier Gun. According to a 2021 report by the Construction Industry Institute, the implementation of innovative fastening technologies, such as rebar tying systems, can reduce labor costs by up to 30%, while also improving structural integrity and durability. As construction projects become increasingly complex, the need for reliable and efficient equipment like the Max Rebar Tier Gun has never been more critical.

Moreover, the growing demand for sustainable and rapid construction methods has put pressure on contractors to adopt tools that not only speed up processes but also ensure high-quality workmanship. A study conducted by McKinsey & Company highlights that construction productivity could increase by 50% through the adoption of automation and improved fastening technologies. By utilizing a Max Rebar Tier Gun, contractors can streamline the rebar tying process, achieving both time savings and superior results—factors that can make a significant difference in project timelines and budgets. In this article, we will explore the top 10 Max Rebar Tier Guns available in the market, offering insights into their features, benefits, and how they can transform your construction projects.

Understanding Rebar Tier Guns: Key Features and Benefits

Rebar tier guns have revolutionized the construction industry, making the process of tying rebar faster, safer, and more efficient. These specialized tools are designed to automate the tying of steel bars, which is critical for the structural integrity of concrete frameworks. According to a recent report by the National Association of Home Builders, nearly 20% of construction delays are attributed to manual labor inefficiencies, indicating a significant need for tools that can enhance productivity on the job site.

Key features of rebar tier guns include their ability to operate with high speed and precision. Many models can tie rebar in a fraction of the time it typically takes a skilled laborer to do the same job, thus reducing labor costs. For instance, a comprehensive study published in the Journal of Construction Engineering and Management found that rebar tier guns can reduce tying time by up to 75%, translating to substantial savings on larger projects. Additionally, these tools often come equipped with adjustable tension settings, improving the versatility and adaptability to different types of rebar configurations.

The benefits of using rebar tier guns extend beyond mere time savings. They significantly enhance worker safety, as the automated operation minimizes the risk of repetitive strain injuries commonly associated with manual tying. Furthermore, the consistent quality of ties produced by these guns contributes to improved structural integrity, which is crucial for meeting stringent building codes. According to a report from McKinsey & Company, construction firms that adopt innovative tools like rebar tier guns see an increase in overall project efficiency by up to 30%, reinforcing their importance in modern construction practices.

Top Brands in Rebar Tier Guns: A Comprehensive Overview

When considering the top brands in rebar tier guns, it is essential to focus on the unique features and technologies that set them apart in the construction industry. These tools have evolved significantly, enhancing productivity and ensuring precision in reinforcement applications. Leading brands consistently invest in research and development, resulting in innovations such as ergonomic designs for improved handling, faster tying speeds, and enhanced durability for long-term use. Understanding these elements can help users choose the right tool for their specific project needs.

Additionally, reliability and service support are critical factors when evaluating rebar tier gun brands. An established brand often provides comprehensive customer service, along with warranties and maintenance options. This commitment to customer satisfaction ensures that users can rely on their equipment for consistent performance, even in the most demanding construction environments. As construction projects continue to grow in complexity, selecting a rebar tier gun from a reputable brand not only improves efficiency but also contributes to overall project success.

Top 10 Max Rebar Tier Guns for Efficient Construction Projects

| Model | Weight (lbs) | Max Capacity (Bars) | Speed (Ties/min) | Power Source | Price Range ($) |

|---|---|---|---|---|---|

| Model A | 10.5 | 4 | 30 | Electric | 300 - 400 |

| Model B | 9.2 | 5 | 35 | Battery | 400 - 500 |

| Model C | 11.0 | 6 | 28 | Pneumatic | 250 - 350 |

| Model D | 10.0 | 5 | 32 | Electric | 350 - 450 |

| Model E | 8.8 | 7 | 40 | Battery | 500 - 600 |

| Model F | 12.0 | 6 | 25 | Pneumatic | 200 - 300 |

| Model G | 9.5 | 4 | 33 | Electric | 310 - 410 |

| Model H | 11.5 | 8 | 20 | Battery | 450 - 550 |

| Model I | 10.8 | 5 | 29 | Pneumatic | 230 - 330 |

| Model J | 8.0 | 3 | 37 | Electric | 270 - 370 |

How to Choose the Right Rebar Tier Gun for Your Projects

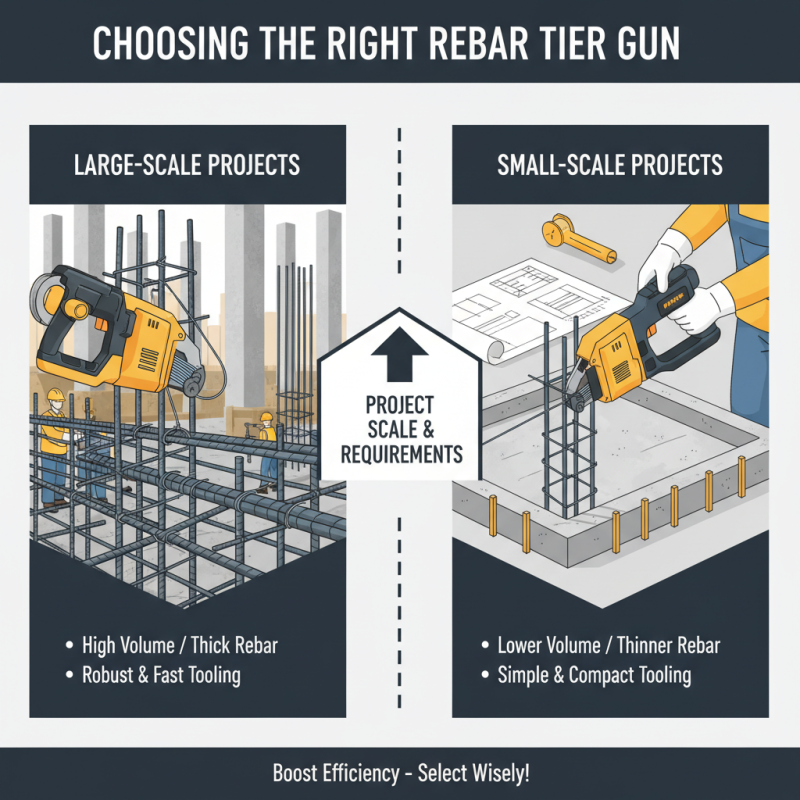

When selecting the right rebar tier gun for your construction projects, it's important to consider several key factors. First, assess the scale and requirements of your project. Different types of rebar tier guns have varying capabilities in terms of rebar size they can handle and the volume of work they can efficiently complete in a day. For larger jobs, a more robust tool with a higher tying speed and capacity may be necessary to maintain productivity, while smaller projects may only require a simpler, more compact solution.

Another essential aspect to consider is the ease of use and maintenance of the rebar tier gun. Look for features such as ergonomic designs that reduce operator fatigue, as well as simple mechanisms for loading and reloading ties. Additionally, consider the availability of replacement parts and the overall durability of the tool. Investing in a reliable rebar tier gun can significantly reduce downtime and improve the efficiency of your construction team, ultimately leading to smoother project completion.

Comparing Electric vs. Pneumatic Rebar Tier Guns for Efficiency

When it comes to selecting the right rebar tier gun for construction projects, the debate between electric and pneumatic models is a crucial factor that can influence efficiency and productivity. Electric rebar tier guns are often praised for their ease of use and portability. They typically operate with battery power, allowing for greater flexibility on job sites without the need for constant air supply. The convenience of electric models means workers can move swiftly between tasks, reducing downtime and enhancing overall workflow.

On the other hand, pneumatic rebar tier guns rely on compressed air, which can lead to more powerful performance in heavy-duty applications. These tools are often favored for their rapid firing rates, making them ideal for large-scale projects where speed is essential. However, they require an air compressor, which can limit mobility and necessitate careful planning regarding air supply logistics. The choice between electric and pneumatic systems ultimately hinges on the specific needs of the project, the available resources, and the desired balance between mobility and power.

Maintenance Tips for Maximizing the Lifespan of Your Rebar Tier Gun

To ensure the longevity and optimal performance of your rebar tier gun, regular maintenance is essential. Start by cleaning the tool thoroughly after each use. Remove any debris, dust, or concrete residue from the gun, especially in the feeding mechanism, to prevent clogs and ensure smooth operation. Additionally, inspect all moving parts regularly for wear or damage, which can hinder functionality and lead to more significant issues down the line.

Another crucial maintenance tip is to lubricate your rebar tier gun periodically. Use a suitable lubricant recommended for your tool type to keep the moving parts functioning smoothly. This helps in reducing friction and prevents corrosion, ultimately extending the life of the gun. Take care to avoid over-lubrication, as excess grease can attract dirt and debris, leading to operational problems.

Lastly, store your rebar tier gun in a dry and secure environment when it's not in use. Exposure to moisture can cause rust and other forms of damage. Investing time in proper maintenance not only enhances the performance of your rebar tier gun but also significantly boosts the efficiency of your construction projects. Taking these simple steps will ensure that your tool remains a reliable asset on the job site for years to come.

Top 10 Max Rebar Tier Guns Efficiency Comparison

This chart compares the efficiency ratings of the top 10 rebar tier guns used in construction projects. Ratings are based on factors like speed, consistency, and ease of use, all crucial for maintaining optimal performance on-site.

Related Posts

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

The Ultimate Guide to Boosting Construction Efficiency with a Stand Up Rebar Tying Machine

-

Top 7 Automatic Rebar Tying Machines for Effortless Construction in 2023

-

2025 Top 10 Max Rebar Tier Machines: Optimize Your Rebar Tying Efficiency with Industry Insights

-

Top 5 Electric Rebar Tying Tools for Efficient and Fast Construction