E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

Essential Guide to Tie Wire Guns: Benefits, Uses, and Buying Tips

In the fast-paced world of construction and landscaping, efficiency and precision are paramount. The Tie Wire Gun has emerged as an essential tool for professionals who require swift and reliable solutions for securing materials, from rebar in concrete structures to securing plants in garden beds. As industry expert John Reynolds aptly puts it, “The Tie Wire Gun transforms a tedious task into a streamlined process, allowing workers to focus on what really matters—getting the job done right.”

With the growing demand for such tools, understanding the benefits and multifunctionality of Tie Wire Guns is crucial. These devices not only enhance productivity but also reduce the physical strain associated with manual tying methods, making them indispensable for contractors and gardeners alike. This essential guide will delve into the various uses of Tie Wire Guns, highlight their advantages, and offer practical tips for making informed purchasing decisions. Whether you're a seasoned professional or a weekend DIY enthusiast, exploring the capabilities of the Tie Wire Gun will undoubtedly elevate your toolkit.

Introduction to Tie Wire Guns: Definition and Functionality

Tie wire guns are specialized tools designed to simplify the process of securing wires and other materials. These devices automate the tying process, allowing users to connect and fasten items more efficiently compared to traditional hand-tying methods. The primary function of a tie wire gun is to deliver a wire loop around materials and then twist and secure that loop, ensuring a tight bond. This capability is particularly useful in various industries, including construction, landscaping, and agriculture, where quick and efficient binding is essential.

The functionality of tie wire guns is largely dependent on their design, which typically includes a spool of wire and a mechanism to create the necessary tension. Many models are engineered to accommodate different wire gauges and types, providing versatility for various applications. Additionally, tie wire guns can reduce strain on the user’s hands, minimize fatigue, and significantly speed up the binding process, making them an essential tool in any professional setting that requires repetitive securing tasks.

Essential Guide to Tie Wire Guns: Benefits, Uses, and Buying Tips

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Tie Wire Gun | A tool designed to quickly and efficiently apply wire to secure plants, structures, or materials. | Increases efficiency, reduces labor time, ensures consistent tensioning. | Landscaping, construction, agriculture, horticulture. |

| Types | Manual and automatic tie wire guns available. | Manual guns are cost-effective; automatic guns increase speed and precision. | Best suited for high-volume applications. |

| Wire Types | Compatible with various wire types including galvanized, stainless steel, and plastic-coated. | Versatility for different applications, corrosion resistance for outdoor use. | Supports different materials based on project requirements. |

| Buying Tips | Consider the intended use, wire type compatibility, ease of use, and budget. | Selecting the right tool maximizes efficiency and performance. | Ensures investment aligns with project needs. |

Key Benefits of Using Tie Wire Guns in Various Industries

Tie wire guns are increasingly becoming essential tools across various industries due to their efficiency and effectiveness in managing wire connections. One of the key benefits of using tie wire guns is the speed at which they can secure wires, significantly reducing labor time and increasing productivity. This is particularly beneficial in industries like construction, agriculture, and landscaping, where quick and reliable tying of wires is critical for structural integrity and safety. The ergonomic design of these tools also minimizes hand fatigue, allowing workers to maintain a consistent level of performance throughout the day.

Moreover, the versatility of tie wire guns makes them suitable for a wide range of applications. In the agricultural sector, for example, they are used to tie plants and secure fencing, making it easier to manage crops and livestock. In construction and electrical work, tie wire guns are invaluable for securing rebar, hanging cable, and organizing wiring systems. With their ability to provide strong, consistent ties without the need for additional tools, tie wire guns streamline the workflow and contribute to a safer working environment by reducing the risk of injuries associated with manual tying methods. As such, investing in a tie wire gun is a practical choice for professionals looking to enhance efficiency and effectiveness in their daily tasks.

Key Benefits of Using Tie Wire Guns in Various Industries

Common Applications of Tie Wire Guns: Where and How to Use Them

Tie wire guns are essential tools in various industries, significantly enhancing efficiency and precision in tasks that require securing materials together. Common applications of tie wire guns include construction, agriculture, and landscaping, where they streamline processes such as bundling rebar, fastening fencing, and securing plant materials. According to a recent industry report, the use of tie wire guns has led to a 30% reduction in labor time for tasks involving repetitive fastening, showcasing their effectiveness in commercial settings.

In the construction sector, tie wire guns are invaluable for tying rebar in concrete work. This method not only ensures structural integrity but also minimizes the risk of injuries associated with manual tying. In agriculture, farmers utilize these guns for securing fencing and trellising plants, which increases productivity and reduces manual effort. As data suggests, incorporating tie wire guns can improve operational efficiency by up to 40%, making them a worthwhile investment for professionals across various fields.

Tips: When selecting a tie wire gun, consider factors such as wire size compatibility and the ease of loading mechanisms. It's also beneficial to choose a model with adjustable tension settings to accommodate different materials. Regular maintenance, including cleaning and lubrication, will enhance the tool's lifespan and performance. Additionally, training staff on proper usage can further optimize the benefits and efficiency gained from this tool.

Essential Features to Look for When Buying a Tie Wire Gun

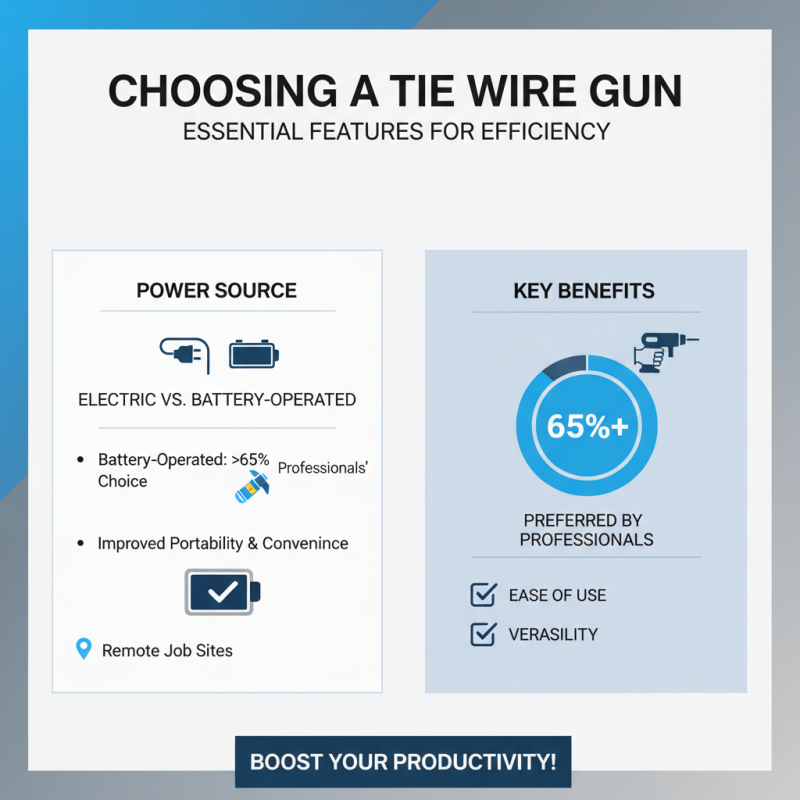

When purchasing a tie wire gun, it's crucial to understand the essential features that can significantly impact your efficiency and overall experience. First and foremost, consider the power source. Tie wire guns can be electric or battery-operated, with industry reports indicating that battery-operated models offer improved portability and convenience in various job sites. According to a market analysis, over 65% of professionals prefer battery-operated options for their ease of use, especially in remote locations without power sources.

Another key feature to evaluate is the adjustable tension settings. A tie wire gun with adjustable settings allows for greater control and adaptability, ensuring that the wire is tightly secured without damaging the materials. Many users report that having this feature can reduce wire waste by up to 30%, thereby increasing project efficiency.

**Tips:** When assessing your options, prioritize ergonomics. A comfortable grip will reduce fatigue during prolonged use, leading to more accurate and quicker applications. Always choose models that provide good safety features, such as automatic shut-off and safety triggers, to protect both you and your work environment. Make sure to read user reviews as they often highlight practical insights that specifications may overlook. Additionally, verify warranty options, as a robust warranty is indicative of manufacturer confidence in their product's longevity and performance.

Maintenance Tips for Longevity and Efficient Use of Tie Wire Guns

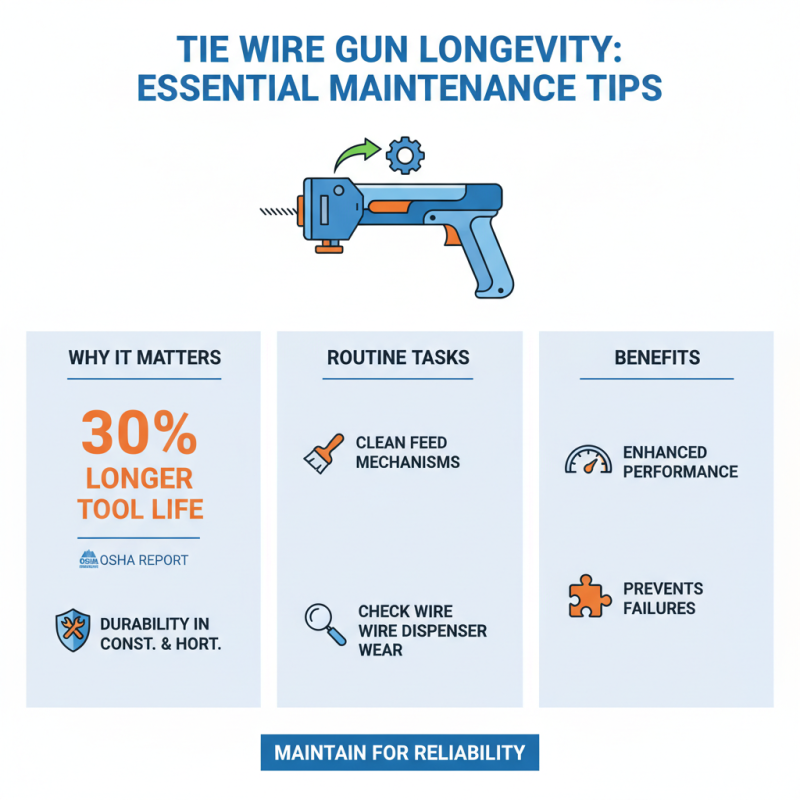

To ensure the longevity and efficient use of tie wire guns, regular maintenance is essential. According to a report by the Occupational Safety and Health Administration (OSHA), proper maintenance practices can extend the lifespan of tools by up to 30%. This is particularly relevant for tie wire guns, as they are frequently used in construction and horticulture, where durability is paramount. Routine tasks such as cleaning the gun's feed mechanisms and checking for wear on the wire dispenser not only enhance performance but also prevent unexpected failures during critical jobs.

Another important aspect of maintenance involves lubrication. Industry standards indicate that tools functioning without sufficient lubrication can experience a significant decrease in efficiency – up to 20%, according to findings from the National Institute for Occupational Safety and Health (NIOSH). Utilizing appropriate lubricants regularly on the moving parts of the tie wire gun helps maintain optimal functionality, ensuring smoother operation and reducing the risk of costly downtime. Additionally, storing the tool in a dry, temperature-controlled environment can prevent rust and other forms of damage, contributing further to its durability and effectiveness in various applications.

Related Posts

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects

-

Exploring the Benefits of Max Rebar Tie Wire Twintier for Efficient Construction Projects

-

Top 10 Tips for Efficient Rebar Tying Techniques

-

2025 Top 10 Max Rebar Tier Machines: Optimize Your Rebar Tying Efficiency with Industry Insights

-

2025 How to Choose the Best Max Rebar Tying Tool for Your Projects

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety