E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

Why You Need an Electric Rebar Tying Tool for Your Construction Projects

In the ever-evolving construction industry, efficiency and safety remain paramount for project success. One pivotal tool that enhances operational effectiveness is the Electric Rebar Tying Tool. According to a 2021 report by the Construction Industry Institute, the use of advanced tools and technologies can boost productivity by up to 30%, making it essential for contractors to embrace innovative solutions. The Electric Rebar Tying Tool exemplifies such innovations, significantly reducing labor time and physical strain associated with manual tying methods.

Additionally, the Occupational Safety and Health Administration (OSHA) has stressed the importance of minimizing ergonomic risks on job sites, highlighting that overexertion contributes to a vast majority of workplace injuries. By utilizing an Electric Rebar Tying Tool, construction teams not only enhance their workflow efficiency but also foster a safer working environment, as these tools are designed to limit repetitive stress and injuries that often plague construction laborers. As the construction landscape continues to adapt to modern challenges, investing in electric tying solutions proves to be a smart choice for those aiming to optimize both performance and safety on their projects.

Benefits of Using Electric Rebar Tying Tools in Construction

The adoption of electric rebar tying tools in construction projects brings forth significant advantages that enhance productivity and efficiency. A report from the National Institutes of Health suggests that integrating electric tools can reduce the time spent on repetitive tasks by up to 60%. This time efficiency is crucial in the fast-paced construction environment where meeting deadlines is essential. Electric rebar tying tools streamline the tying process, allowing workers to complete more tasks in a shorter timeframe, ultimately leading to project completion ahead of schedule.

Moreover, the ergonomic design of electric rebar tying tools contributes to the health and safety of the workforce. According to the Occupational Safety and Health Administration (OSHA), musculoskeletal disorders are a leading cause of injury in the construction industry, accounting for nearly 30% of all workplace injuries. The use of electric rebar tying tools minimizes the physical strain associated with manual tying, significantly reducing the risk of injury. By enabling workers to perform tasks that demand less manual effort, these tools not only improve worker morale but also reduce downtime associated with injuries and injuries-related costs.

In addition to these benefits, electric rebar tying tools also enhance the consistency and quality of work. The precision involved in using these tools ensures that ties are made uniformly, preventing potential structural issues that could arise from inconsistent tying. A study published by the American Society of Civil Engineers estimates that up to 20% of structural failures are linked to inadequate connections. By leveraging the capabilities of electric rebar tying tools, construction teams can help mitigate these risks, resulting in more reliable and enduring structures.

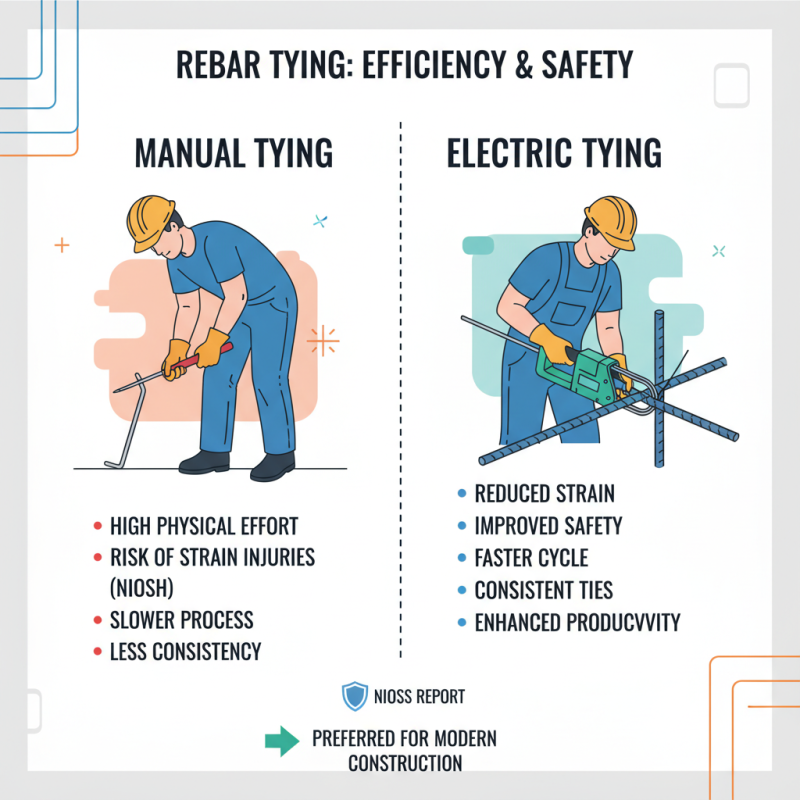

Comparison of Electric vs. Manual Rebar Tying Methods

When it comes to rebar tying methods in construction, the choice between electric and manual options significantly impacts efficiency and worker safety. A report by the National Institute for Occupational Safety and Health (NIOSH) indicates that manual tying often requires considerable physical effort, leading to a higher incidence of repetitive strain injuries. Electric rebar tying tools, however, can reduce the strain on workers by automating the process, which results in improved job site safety and enhanced productivity.

In terms of operational efficiency, studies show that electric rebar tying tools can complete a tie in as little as 0.5 seconds compared to 2-3 seconds for manual tying. This translates to a productivity increase of up to 300% under optimal conditions. According to the Associated General Contractors of America, contractors report that transitioning to electric tools leads to significant reductions in project timelines, allowing for faster completion and improved overall project management. Moreover, the consistent tension applied by electric tools ensures stronger and more consistent ties, meeting structural standards more effectively than manual techniques.

Key Features to Look for in an Electric Rebar Tying Tool

When selecting an electric rebar tying tool for your construction projects, several key features should be at the forefront of your decision-making process. Firstly, consider the tool's tying speed; many models can complete up to 2,000 ties per hour, significantly enhancing workflow efficiency. According to a report by the Construction Industry Institute, the implementation of automated tools such as electric rebar tying machines can reduce labor costs by approximately 30%, making them a smart investment for large-scale projects.

Another crucial feature is the battery life and charging speed. A reliable electric rebar tying tool should offer a battery life that allows for extended use without frequent interruptions. Many modern tools can operate for several hours on a single charge, providing the necessary power to tackle demanding jobs. Additionally, the weight and ergonomic design of the tool play a vital role in user comfort and prolonged use. Tools that weigh under 5 pounds and feature grip designs can alleviate strain on workers, reducing the risk of injury and increasing productivity, as highlighted in studies by the Occupational Safety and Health Administration (OSHA).

Lastly, ensure that the tool is equipped with adjustable tying tension settings, allowing for versatility based on different rebar sizes and project requirements. Tools with user-friendly interfaces and quick-release mechanisms simplify operation, making it easier for workers to adapt to varying project demands. As per industry analyses, the adoption of such user-centric features leads to a 20% increase in overall job site efficiency, emphasizing the importance of choosing the right electric rebar tying tool for optimal project outcomes.

Safety Considerations When Using Electric Rebar Tying Tools

When using electric rebar tying tools, safety should always be a top priority on any construction site. These powerful tools can significantly enhance efficiency, but they also come with potential risks if not handled correctly. It's crucial to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and sturdy footwear to protect yourself from accidental injuries. Additionally, make sure to conduct pre-use inspections to ensure that the tool is in good working condition, checking for any potential defects or malfunctions.

Tips for safe operation of electric rebar tying tools include maintaining a clear work area free from hazards that could lead to trips or slips. Always be aware of your surroundings and ensure that other workers are at a safe distance when operating the tool. Familiarize yourself with the specific safety features of the tool, such as safety locks or emergency shut-offs, to enhance your control over the equipment. Furthermore, proper training is essential; ensure that all team members are educated on the safe handling and operation of electric rebar tying tools to minimize risk.

In case of any malfunction or unexpected behavior of the tool, it’s important to stop use immediately and report the issue to a supervisor. Regular maintenance and adherence to safety guidelines not only protect individual workers but also foster a safer working environment for the entire team. Prioritizing safety while utilizing electric rebar tying tools will lead to more effective and risk-free construction processes.

Benefits of Electric Rebar Tying Tools Compared to Manual Methods

Cost Efficiency and Productivity Gains in Construction Projects

In today's rapidly evolving construction landscape, efficiency and productivity are paramount. An electric rebar tying tool significantly enhances these aspects by automating what was once a labor-intensive task. Traditional tying methods can consume valuable time and require considerable manual effort, often resulting in inconsistencies and fatigue among workers. By utilizing an electric tool, the tying process becomes streamlined, allowing for quicker assembly and thus reducing overall project timelines.

Moreover, the cost efficiency associated with electric rebar tying tools cannot be overlooked. With faster tying capabilities, labor costs decrease as fewer workers are needed to complete the same task in less time. This also minimizes the likelihood of errors that can lead to costly rework later in the project. Additionally, high-quality ties contribute to structural integrity, which ultimately reduces long-term costs related to maintenance and repairs. By investing in such technology, construction firms not only boost their productivity but also foster a more sustainable approach to managing resources and budgets in ongoing and future projects.

Why You Need an Electric Rebar Tying Tool for Your Construction Projects - Cost Efficiency and Productivity Gains in Construction Projects

| Parameter | Electric Rebar Tying Tool | Manual Tying Method |

|---|---|---|

| Average Cost (per unit) | $150 | $30 (Tools only) |

| Average Time per Tying (seconds) | 2 | 10 |

| Ties Completed per Hour | 180 | 120 |

| Labor Cost per Hour | $20 | $20 |

| Total Labor Cost for Ties (1000 ties) | $200 | $500 |

| Maintenance Cost (Annual) | $50 | N/A |

Related Posts

-

Top 5 Electric Rebar Tying Tools for Efficient and Fast Construction

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

Max Rebar Tying Tool: The Ultimate Solution for Fast and Efficient Rebar Tying

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects

-

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs

-

How to Choose the Best Rebar Tying Tool for Your Construction Projects