E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

What is an Electric Rebar Tying Tool and How Does it Improve Your Efficiency

In the fast-paced world of construction, efficiency is paramount, and the tools we choose can significantly impact our productivity. One such innovation is the Electric Rebar Tying Tool, a game changer for professionals in the rebar assembly process. "The Electric Rebar Tying Tool not only saves time but also enhances the quality of our work," says John Smith, a leading expert in construction technology. His insights highlight the transformative nature of this tool in modern construction practices.

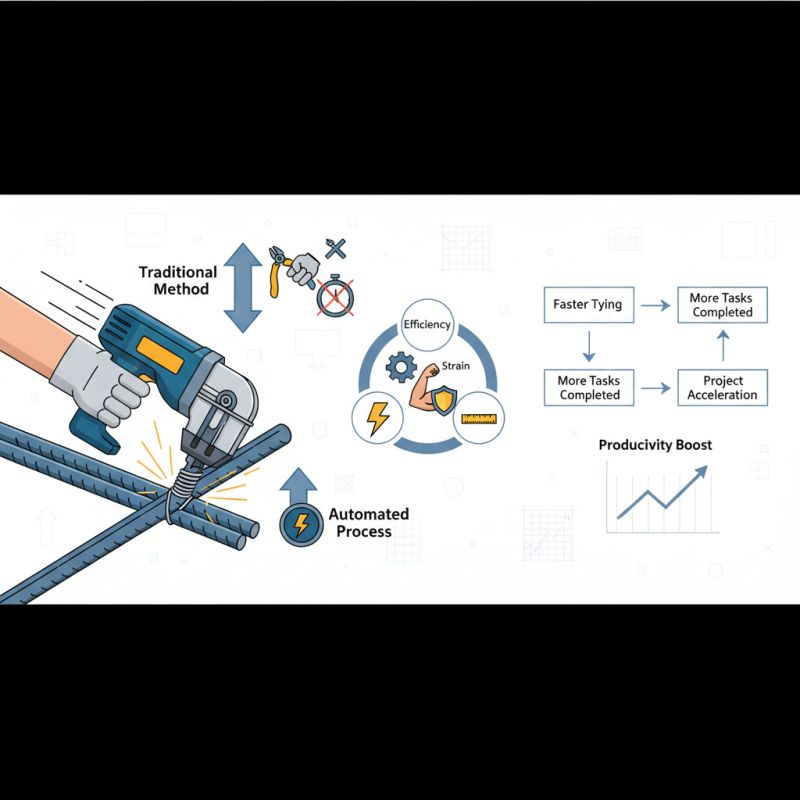

The Electric Rebar Tying Tool automates the tying process, reducing the manual labor typically involved in securing rebar. By streamlining this crucial part of rebar installation, it allows workers to focus on other essential tasks, ultimately boosting overall project efficiency. According to industry experts, the traditional method of tying rebar is not only labor-intensive but can also lead to inconsistencies, potentially compromising structural integrity. With the adoption of the Electric Rebar Tying Tool, professionals can expect increased precision and decreased physical strain on laborers.

As construction sites continue to evolve with technological advancements, the Electric Rebar Tying Tool stands out as an essential addition to any toolkit. Its ability to enhance workflow while maintaining high standards of craftsmanship reaffirms the importance of innovation in the construction industry, making it a worthwhile investment for those seeking to improve their operational effectiveness.

Definition and Functionality of Electric Rebar Tying Tools

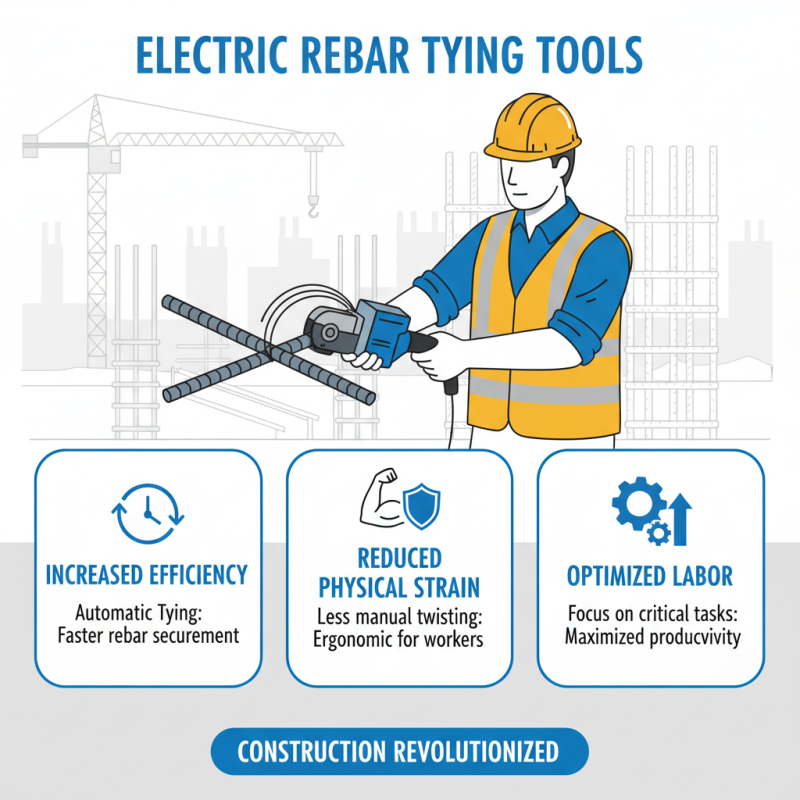

Electric rebar tying tools are specialized devices designed to streamline the process of tying rebar in construction projects. These tools utilize electric power to automate the tying process, which traditionally relied on manual labor. The primary function of an electric rebar tying tool is to securely fasten rebar together, ensuring that structures maintain their integrity and stability during construction. The tool wraps high-strength wire around the rebars and efficiently ties them, which can help reduce labor costs and increase safety on the job site.

According to a report by the National Institute of Building Sciences, labor productivity in the construction industry has been on the decline, with many workers facing the physical strain associated with repetitive tasks. Electric rebar tying tools address this issue by enhancing worker efficiency, allowing for quicker project turnaround. An industry study indicates that using these tools can improve tying speed by up to 5 times compared to manual methods, which not only shortens the construction timeline but also helps in reallocating labor resources to more complex tasks. Furthermore, the ergonomic design of electric tying tools minimizes strain injuries among workers, promoting a safer working environment.

Key Features of Electric Rebar Tying Tools That Enhance Performance

Electric rebar tying tools have revolutionized the construction industry by significantly enhancing efficiency on job sites. One of the key features of these tools is their automatic tying mechanism, which allows users to quickly secure rebar in place without the labor-intensive manual twisting of wire. This automation not only saves time but also reduces physical strain on workers, allowing them to focus on other critical tasks.

Another important feature is the battery-powered functionality of electric rebar tying tools. This portable design enables users to operate the tool without being tethered to a power source, making it suitable for a variety of construction environments. The tool's lightweight construction further adds to its convenience, allowing for easy handling and maneuverability in tight spaces.

Tip: When using an electric rebar tying tool, ensure that the battery is fully charged before starting your project to avoid interruptions. Additionally, practice using the tool on scrap pieces to familiarize yourself with its settings and operation, which can help boost your productivity on the job site.

Comparison: Electric Rebar Tying Tools vs. Manual Tying Methods

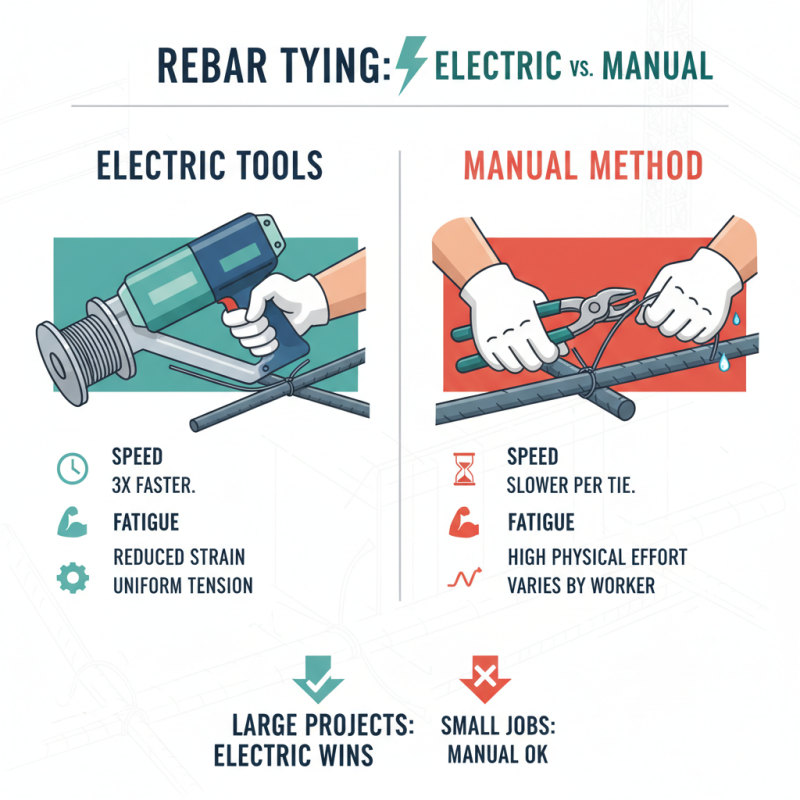

When choosing between electric rebar tying tools and traditional manual tying methods, several factors come into play that can significantly impact efficiency at construction sites. Electric rebar tying tools leverage power and precision, allowing workers to tie rebar quickly and with consistent tension. This technology eliminates the physical strain associated with manual tying and drastically reduces the time spent on each tie, making it especially beneficial for large-scale projects where hundreds of ties are needed.

In contrast, manual tying methods rely solely on human effort, requiring workers to use pliers or wire to secure the rebar by hand. While this method can be effective for smaller tasks or in areas with limited access, it is time-consuming and often leads to inconsistent results. Manual tying also increases the risk of fatigue, which can affect the overall productivity and safety of the team.

Tips for maximizing efficiency include conducting regular training sessions for staff on using electric tools correctly and investing in quality equipment that caters to the specific needs of the job. Additionally, organizing rebar placement before tying can streamline the process, minimizing downtime and ensuring a smoother workflow. Proper maintenance of both electric tools and manual techniques can prolong their lifespan while enhancing performance on the job site.

Benefits of Using Electric Rebar Tying Tools in Construction Projects

Electric rebar tying tools have revolutionized the way construction projects are managed, providing significant advantages over traditional methods. One of the primary benefits of using these tools is the dramatic increase in efficiency. Manual tying can be labor-intensive and time-consuming, particularly on large-scale projects where rebar placement is critical. Electric tools automate the tying process, allowing workers to complete tasks faster and with greater consistent quality. This efficiency not only speeds up project timelines but also helps reduce labor costs, as fewer workers are needed to achieve the same outputs.

In addition to saving time and labor, electric rebar tying tools enhance the durability of the ties themselves. The consistent tension and precision achieved through electric tying ensure that the rebar is securely fastened, reducing the risk of structural failures that can occur with inconsistent manual tying. Furthermore, these tools often come with features that improve user comfort and safety, such as ergonomic designs that minimize strain during prolonged use. Overall, the integration of electric rebar tying tools into construction workflows leads to improved project outcomes, highlighting their importance in modern construction practices.

What is an Electric Rebar Tying Tool and How Does it Improve Your Efficiency - Benefits of Using Electric Rebar Tying Tools in Construction Projects

| Feature | Traditional Tool | Electric Rebar Tying Tool |

|---|---|---|

| Tying Speed | 1-2 ties per minute | 3-4 ties per minute |

| Weight | 6-8 lbs | 4-6 lbs |

| Ease of Use | Requires manual effort | Automated, minimal effort |

| Battery Life | N/A | Up to 300 ties per charge |

| Durability | Moderate | High, designed for rugged use |

| Cost | $50 - $100 | $300 - $600 |

Tips for Maximizing Efficiency When Using Electric Rebar Tying Tools

When utilizing electric rebar tying tools, maximizing efficiency is crucial for productive construction work. One key tip is to ensure that all necessary equipment and materials are easily accessible before starting the job. This includes pre-cut rebar and tying wire organized in a manner that minimizes movement around the site. Having a designated workspace helps streamline the process, allowing you to focus on the task at hand without unnecessary interruptions.

Another effective strategy involves proper training and practices for users of the electric rebar tying tool. Familiarizing yourself with the tool's features and functions can significantly enhance speed and accuracy. Regular maintenance checks to ensure the tool is in optimal working condition will also prevent downtimes. Implementing a rhythm when tying rebar can help improve muscle memory, allowing for quicker and more consistent performance throughout the day. Investing time in mastering these techniques will contribute to a more efficient workflow on the construction site.

Related Posts

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

2025 Top 10 Max Rebar Tier Machines: Optimize Your Rebar Tying Efficiency with Industry Insights

-

Top Electric Rebar Tying Tools of 2025: What to Look For

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects

-

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs