E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

What is an Electric Rebar Tying Machine and How Does It Improve Efficiency?

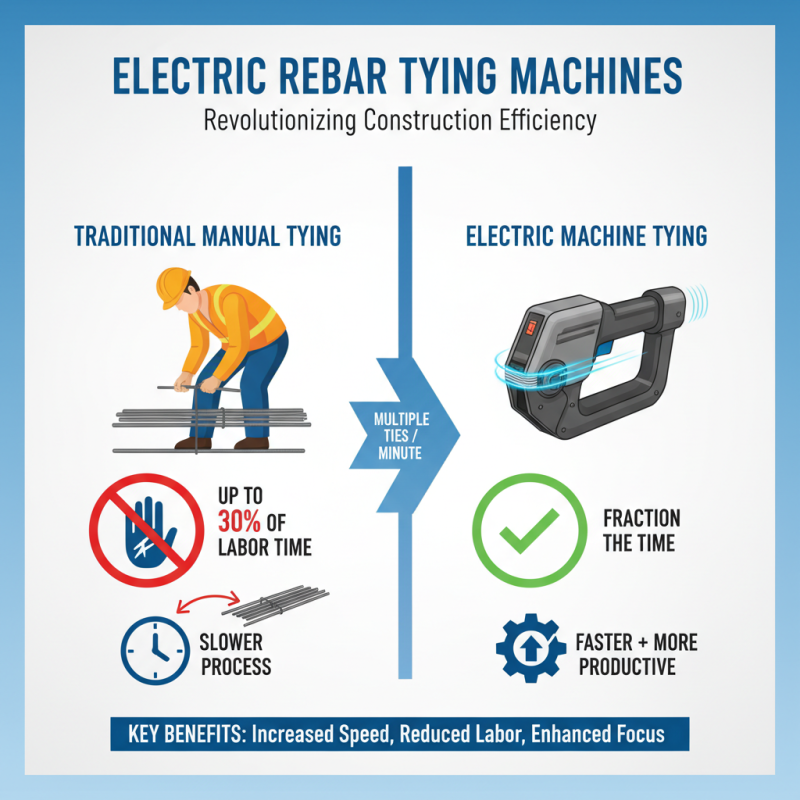

The construction industry has seen a significant evolution in its operational techniques, particularly with the advent of advanced machinery designed to enhance productivity and efficiency in rebar installation. One such innovation is the Electric Rebar Tying Machine. According to a recent report by the Global Construction Industry Trends, the mechanization in construction has resulted in a productivity increase of up to 30% in some sectors. This statistic underscores the growing reliance on specialized equipment, which streamlines labor-intensive tasks, and having an Electric Rebar Tying Machine is a key component of this shift.

These machines have revolutionized how contractors approach rebar tying, reducing the physical strain on workers while increasing precision and speed. Statistics reveal that manual tying can take up to 20 seconds for each connection, whereas an Electric Rebar Tying Machine can accomplish the same task in under 5 seconds. This dramatic improvement contributes significantly to project timelines and labor costs, making it an indispensable tool on modern construction sites. As the industry continues to seek ways to optimize output and maintain high safety standards, the Electric Rebar Tying Machine stands out as a pivotal innovation that aligns with the needs of contemporary construction practices.

What is an Electric Rebar Tying Machine?

An Electric Rebar Tying Machine is an innovative tool specifically designed to streamline the process of tying rebar in construction projects. Unlike traditional manual methods, this machine automates the binding process, significantly reducing labor time and improving overall efficiency on-site. Typically powered by a rechargeable battery, the electric machine can quickly twist and tie wires to secure rebars in place, offering a consistent and reliable connection that adheres to safety standards.

When using an Electric Rebar Tying Machine, it's important to keep a few tips in mind for optimal performance. First, ensure that the wire tension is properly adjusted before starting your tasks, as this will impact the integrity of the ties. Second, familiarize yourself with the machine's settings and features, as many modern machines offer various modes for different tying needs. Proper maintenance is also crucial; regularly clean and check the machine to prevent any malfunctions that could hinder your work efficiency.

By leveraging the capabilities of an Electric Rebar Tying Machine, construction teams can enhance productivity while minimizing the risk of errors associated with manual tying. This sophisticated equipment not only improves safety but also allows workers to focus on other critical aspects of a project, ultimately leading to better construction outcomes.

Key Features of Electric Rebar Tying Machines

Electric rebar tying machines represent a significant advancement in construction technology, enhancing efficiency and productivity on job sites. One of the key features of these machines is their ability to perform multiple ties per minute, drastically reducing labor time. According to industry reports, traditional manual tying methods can require up to 30% of a worker's time on a project, while electric machines can tie rebar bundles in a fraction of that time. This not only speeds up the construction process but also allows workers to focus on more critical tasks, further improving overall productivity.

Another vital feature of electric rebar tying machines is their consistent tying strength and quality. Manual tying can lead to variations in tension, potentially compromising structural integrity. In contrast, electric machines deliver uniform ties every time, with precise tension settings that can be adjusted based on the requirements of different projects. Studies indicate that using electric tying methods can decrease error rates by up to 40%, leading to safer and more reliable construction outcomes. Moreover, the ergonomic design of many electric tying machines reduces strain on workers, promoting better safety and job satisfaction in demanding construction environments.

Benefits of Using Electric Rebar Tying Machines for Construction

Electric rebar tying machines are transforming the construction industry by significantly enhancing efficiency and productivity on job sites. One of the primary benefits of using these machines is the speed at which they operate. Unlike traditional manual tying methods, which can be time-consuming and labor-intensive, electric rebar tying machines can complete tasks in a fraction of the time. This rapid operation allows workers to focus on other critical aspects of their projects, streamlining the overall construction process.

Moreover, electric rebar tying machines reduce the physical strain on workers, minimizing the risk of injuries associated with repeated manual tying. The ergonomic design of these machines means that they require less manual effort, enabling crews to work longer and more effectively without the fatigue that manual operations can cause. This aspect not only improves worker safety but also enhances overall job satisfaction, leading to a more motivated workforce.

Additionally, the precision and consistency offered by electric rebar tying machines contribute to the structural integrity of constructions. With automated tying, the likelihood of human error is drastically reduced, ensuring that all ties are executed uniformly and reliably. This uniformity in tying enhances the durability of frameworks, leading to more robust construction outcomes and ultimately saving costs related to repairs or rework in the future.

How Electric Rebar Tying Machines Enhance Construction Efficiency

Electric rebar tying machines have revolutionized the construction industry by significantly enhancing productivity and efficiency. These machines automate the labor-intensive process of tying rebar, which is essential for reinforcing concrete structures. Traditional manual tying methods are not only time-consuming but also physically demanding, leading to fatigue among workers. By using electric rebar tying machines, construction teams can drastically reduce the time spent on this task, allowing them to focus on other critical aspects of the project.

The efficiency gains from using electric rebar tying machines are multifaceted. First, they improve the speed of the tying process, enabling workers to complete jobs much faster than manual tying would allow. This accelerated pace means that projects can be completed within tighter deadlines, which is essential in today’s competitive construction environment. Additionally, these machines offer consistent and reliable performance, ensuring that ties are uniform and secure, which enhances the overall quality of the construction work. The ergonomic design of electric rebar tying machines also reduces the physical strain on workers, leading to improved safety and reduced injury rates on-site. Overall, the integration of electric rebar tying machines in construction processes not only boosts operational efficiency but also contributes to safer and higher-quality building practices.

Electric Rebar Tying Machines Efficiency Comparison

Comparison: Electric vs. Manual Rebar Tying Methods

When comparing electric and manual rebar tying methods, efficiency becomes a critical factor in construction projects. A report by the National Institute of Standards and Technology (NIST) highlights that manual rebar tying can consume up to 65% of a laborer's time on a job site. This inefficiency not only affects project timelines but also increases labor costs significantly. In contrast, electric rebar tying machines can complete the same tying task in a fraction of the time, allowing workers to enhance their productivity and focus on other essential aspects of construction.

Furthermore, studies conducted by the American Concrete Institute (ACI) indicate that electric rebar tying machines can reduce the tying time by up to 75% compared to traditional methods. This advancement not only accelerates the workflow but also improves the overall safety of workers. With fewer manual operations, there is a reduced risk of repetitive strain injuries, a common issue in manual rebar tying. Consequently, integrating electric machines not only boosts efficiency but also contributes to a safer working environment, making them an attractive choice for modern construction practices.

What is an Electric Rebar Tying Machine and How Does It Improve Efficiency? - Comparison: Electric vs. Manual Rebar Tying Methods

| Method | Speed (ties/minute) | Operator Fatigue | Cost Efficiency | Ease of Use |

|---|---|---|---|---|

| Electric Rebar Tying Machine | 30-40 | Low | High | Very Easy |

| Manual Rebar Tying | 10-15 | High | Moderate | Requires Skill |

Related Posts

-

The Ultimate Guide to Boosting Construction Efficiency with a Stand Up Rebar Tying Machine

-

Revolutionizing Construction: How Electric Rebar Tying Machines Boost Productivity by 50% in Modern Projects

-

Max Rebar Tier: Revolutionizing Rebar Tying Efficiency with 30% Faster Workflows

-

Exploring the Benefits of Max Rebar Tie Wire Twintier for Efficient Construction Projects

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

2025 How to Choose the Best Max Rebar Tying Tool for Your Projects