E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

How to Choose the Best Rebar Tying Tool for Your Construction Projects

In the construction industry, the efficiency and safety of projects significantly hinge on the tools used for reinforcing materials, particularly rebar. According to a report by Estimates and Construction Industry Analysis, the demand for rebar tying tools is expected to grow by over 5% annually, driven by the increasing number of infrastructure projects worldwide. Among these tools, the Rebar Tying Tool Twintier has gained attention for its superior speed and reliability in securing rebar connections. This tool reduces the time spent on manual tying, allowing workers to focus on other crucial aspects of their projects.

As construction firms seek to enhance productivity and minimize labor costs, selecting the right rebar tying tool becomes essential. An industry study highlighted that using advanced tools can lead to a 30% reduction in labor hours, drastically impacting project timelines and budgets. Construction managers must consider factors such as ease of use, durability, and tying effectiveness when choosing a rebar tying tool. As the competition in the market intensifies, understanding the technological advancements and user-specific needs will play a vital role in making informed decisions. Emphasizing a strategic approach to tool selection is paramount for achieving success in construction projects.

Understanding the Different Types of Rebar Tying Tools Available

When selecting the best rebar tying tool for your construction projects, it’s crucial to understand the various types of tools available in the market. Rebar tying tools can generally be classified into three categories: manual tying tools, battery-powered tools, and pneumatic tools. Manual tying tools are the most traditional option, requiring physical effort to twist wire and secure rebar. These tools are typically lightweight, cost-effective, and easy to use in tight spaces, making them a popular choice for smaller projects.

Battery-powered rebar tying tools have been gaining traction in the industry due to their efficiency and ease of use. According to a report by the Construction Industry Institute, the adoption of advanced tools like battery-operated devices can increase productivity on construction sites by up to 30%. These tools significantly reduce the amount of time spent on tying rebar, thus allowing for faster project completion. They are particularly advantageous for large-scale projects where the volume of rebar tying can be substantial.

Pneumatic rebar tying tools are also valuable for heavy-duty projects. Leveraging compressed air, these tools can quickly and efficiently tie rebar with minimal effort from the operator. Industry studies suggest that pneumatic tools can enhance performance and reduce labor costs by approximately 25%, especially in large-scale applications. Understanding these different tool types and their implications on efficiency and cost can significantly influence the choice for rebar tying in your next construction project.

Rebar Tying Tool Comparison

Evaluating Tool Features: Manual vs. Automatic Tying Options

When choosing a rebar tying tool, understanding the differences between manual and automatic tying options is crucial for optimizing efficiency and ensuring quality in construction projects. Manual tying tools are typically more affordable and straightforward, relying on the operator's skill to twist and tie rebar securely. They are ideal for small-scale projects where the volume of ties is manageable, allowing for precision without the need for complex machinery. However, the downside is that manual tools can be labor-intensive and require a significant amount of time and physical effort, potentially increasing the overall labor costs for larger jobs.

On the other hand, automatic tying tools bring a significant advantage in terms of speed and ease of use. These tools are designed to streamline the tying process, allowing workers to complete jobs more rapidly, which can lead to increased productivity. Automatic options usually have a mechanism that automatically ties the rebar with consistent tension, reducing the chance of human error and ensuring uniformity in each tie. While the initial investment in automatic tools may be higher, they can save money in labor costs over time, especially on large projects where efficiency is paramount. Ultimately, the choice between manual and automatic tying options will depend on the specific requirements of the construction project, including scale, budget, and desired efficiency level.

How to Choose the Best Rebar Tying Tool for Your Construction Projects

| Feature | Manual Tying Tool | Automatic Tying Tool |

|---|---|---|

| Tying Speed | Up to 20 ties/min | Up to 50 ties/min |

| Weight | 2 lbs | 5 lbs |

| Ease of Use | Moderate | High |

| Power Source | None | Rechargeable Battery |

| Cost | $30 | $150 |

| Durability | Good | Excellent |

| Ideal Usage | Small Projects | Large Construction Sites |

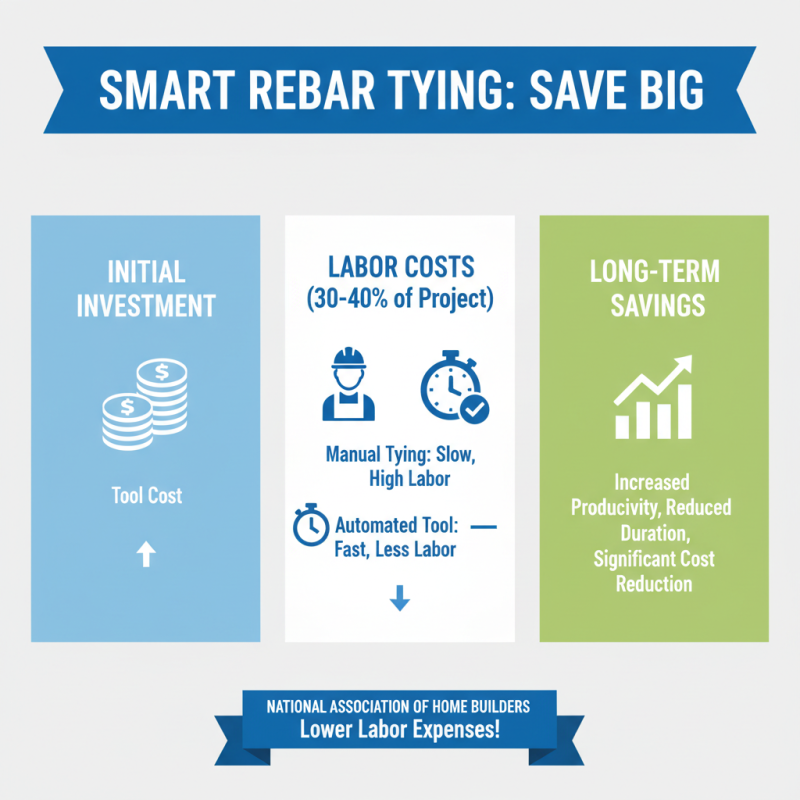

Assessing Cost-Effectiveness: Investment vs. Long-Term Savings

When selecting the best rebar tying tool for your construction projects, it's crucial to assess not only the initial investment but also the long-term savings it can provide. According to a report from the National Association of Home Builders, labor costs typically account for 30-40% of total construction expenses. By investing in a high-quality rebar tying tool, contractors can enhance productivity, reduce labor hours, and ultimately lower these expenses significantly over time. For instance, tools that automate the tying process can perform the same task in a fraction of the time compared to manual tying, leading to a measurable increase in project efficiency.

**Tips**: When evaluating tools, consider their durability and maintenance requirements. A tool that requires frequent repairs or replacement can quickly diminish cost-effectiveness. Look for user reviews and cost-per-use analyses to make informed decisions about your investment.

Additionally, the long-term savings can extend beyond labor costs. A study by the Associated General Contractors of America highlights that projects utilizing automatic tying tools have reported up to a 20% reduction in material waste due to more precise tying. This not only contributes to a greener project but also lowers overall material costs. Assessing the ROI of a durable, efficient rebar tying tool should include these factors, offering a comprehensive view of its financial impact on your projects.

**Tips**: Assess different tool features like speed, ergonomics, and compatibility with various rebar sizes. The right tool can make the tying process safer and more comfortable for workers, which is an often overlooked factor in overall cost assessments.

Examining Ergonomics and Usability for Labor Efficiency

When selecting a rebar tying tool for your construction projects,

ergonomics and

usability should be at the forefront of your decision-making process.

A well-designed tool can significantly reduce physical strain during repetitive tasks,

ultimately enhancing labor efficiency. Look for features such as padded grips

and adjustable handles, which allow for comfortable use over extended periods.

The weight distribution of the tool is also crucial; it should be balanced to minimize fatigue

while maximizing control.

Tips: When trying out various tools, pay attention to how they feel in your hand.

Ideally, the grip should fit comfortably within your palm without causing discomfort or cramping.

Additionally, test the tool's operation to ensure that it allows for smooth and swift tying motions.

A tool that facilitates a natural wrist movement can lessen the risk of repetitive strain injuries,

allowing workers to remain productive throughout the day.

Moreover, consider the tool's design for accessibility and efficiency. Features like

quick-release mechanisms can save precious time

when switching between tasks. A compact size may also enhance portability, making it easier

to use in tight or congested workspaces. Prioritize these ergonomic attributes to ensure that

your workforce can perform their best without sacrificing comfort or safety.

Reviewing Industry Standards and Safety Compliance for Rebar Tools

When selecting a rebar tying tool for construction projects, adherence to industry standards and safety compliance is paramount. Tools should meet regulatory guidelines set by organizations that govern construction practices, ensuring they are safe to use and effective at completing tasks. This includes compliance with specifications regarding materials, design, and overall performance. By choosing tools that adhere to these standards, contractors can minimize the risks of accidents and ensure the longevity and reliability of the equipment.

In addition to meeting industry standards, safety features should be a critical consideration. Tools should include elements that protect users from potential hazards, such as mechanical failures or accidental injuries. Features like ergonomic designs, safety locks, and protective guards can significantly enhance user safety. Furthermore, it’s essential to ensure that workers are adequately trained in using the tools correctly, as improper use can lead to dangerous situations, regardless of how compliant a tool may be with regulations. Ultimately, prioritizing safety compliance not only fosters a safer working environment but also contributes to the overall efficiency of construction projects.

Related Posts

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

Top 5 Electric Rebar Tying Tools for Efficient and Fast Construction

-

Max Rebar Tying Tool: The Ultimate Solution for Fast and Efficient Rebar Tying

-

Top Electric Rebar Tying Tools of 2025: What to Look For

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects

-

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs