E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

How to Choose the Best Max Rebar Tying Tool for Your Project

Choosing the right Max Rebar Tying Tool for your construction project is crucial for efficiency and quality. As industry expert John McCarthy, a leading authority in construction tools, states, "Selecting the right tying tool can significantly enhance your workflow and improve the overall structural integrity of your work." With a plethora of options available on the market, understanding the features and benefits of various Max Rebar Tying Tools can be overwhelming.

In an industry where precision and speed are paramount, making an informed decision is vital. The right Max Rebar Tying Tool not only impacts the speed of your project but also influences the safety and durability of the final product. Whether you are a seasoned contractor or a DIY enthusiast, knowing the key factors to consider—such as tool type, weight, durability, and ease of use—will empower you to select the tool that best fits your specific requirements. This guide aims to equip you with the insights needed to navigate the selection process effectively, ensuring that you invest in a Max Rebar Tying Tool that meets your project's demands and enhances your overall productivity.

Understanding the Different Types of Max Rebar Tying Tools

When selecting a Max rebar tying tool, it's essential to understand the various types available to ensure you choose the most effective one for your project.

Common types include manual tying tools, battery-operated tools, and pneumatic tools.

Manual tools typically require more effort and are best suited for smaller jobs or tight spaces where machinery may not fit. They are also more cost-effective for those just starting or with limited budgets.

Battery-operated tools provide a good balance of ease of use and portability,

allowing workers to move freely on the job site without being tethered by cords. They offer quicker tying, improving overall efficiency, especially on larger projects.

Pneumatic tools are the most powerful option, utilizing compressed air for rapid and consistent tying. They are ideal for high-volume applications where time is critical.

Tips: Before purchasing, consider the scale of your project and the volume of ties required.

It's also wise to evaluate the availability of power sources on the job site for battery-operated and pneumatic tools.

Additionally, always check user reviews and practice with the tool to familiarize yourself with its operation, maximizing your productivity while ensuring quality work.

Key Features to Consider When Selecting a Rebar Tying Tool

When selecting a rebar tying tool for your project, it's crucial to consider several key features that can enhance efficiency and effectiveness. First and foremost, the tool's tying speed is essential. A faster tying tool can significantly reduce the time required for rebar assembly, which is particularly beneficial for large-scale projects. Look for tools that offer adjustable tying speeds, as this flexibility allows you to adapt to various working conditions and materials.

Another important feature to consider is the tool's durability and build quality. Rebar tying tools should withstand the rigors of construction environments, so pay attention to the materials used in their construction. A robust design not only ensures longevity but also minimizes maintenance and replacement costs over time. Additionally, consider ergonomic factors, such as grip comfort and tool weight, which can impact user fatigue during prolonged use. A well-balanced and lightweight tool can greatly enhance productivity, allowing workers to stay focused and efficient throughout the tying process.

How to Choose the Best Max Rebar Tying Tool for Your Project

| Feature | Importance | Recommended Range |

|---|---|---|

| Tying Speed | High | 20-30 ties per minute |

| Weight | Medium | 3-7 lbs |

| Battery Life | High | 2-8 hours |

| Wire Size Compatibility | High | 0.8-1.2 mm |

| Ease of Use | High | User-friendly interface |

| Durability | High | Metal casing recommended |

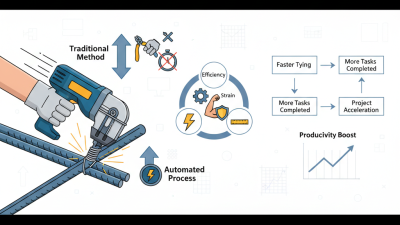

Evaluating the Efficiency and Speed of Rebar Tying Tools

When selecting a rebar tying tool for your construction project, evaluating the efficiency and speed of these tools is essential. Tying rebar manually can be labor-intensive and time-consuming, leading to potential delays in your project. Therefore, tools designed to automate this process are not only beneficial for maintaining productivity but also for reducing the physical strain on workers. A high-quality rebar tying tool can accurately and consistently tie rebar within seconds, significantly enhancing workflow and allowing for more time to focus on other critical tasks.

Moreover, the efficiency of a rebar tying tool is often linked to its ease of use and the speed at which it can complete ties. The better models are designed with user-friendly features that facilitate quick operation, minimizing the learning curve for new users. Additionally, these tools often come with adjustable settings to accommodate different wire sizes and tying techniques, which enhances versatility on diverse job sites. By thoroughly assessing these aspects, users can choose a tool that not only meets their specific project demands but also contributes to an overall increase in productivity and efficiency on the job.

Efficiency and Speed of Rebar Tying Tools

This chart displays the efficiency (number of ties per hour) and speed (time taken per tie in seconds) of different types of rebar tying tools based on user evaluations.

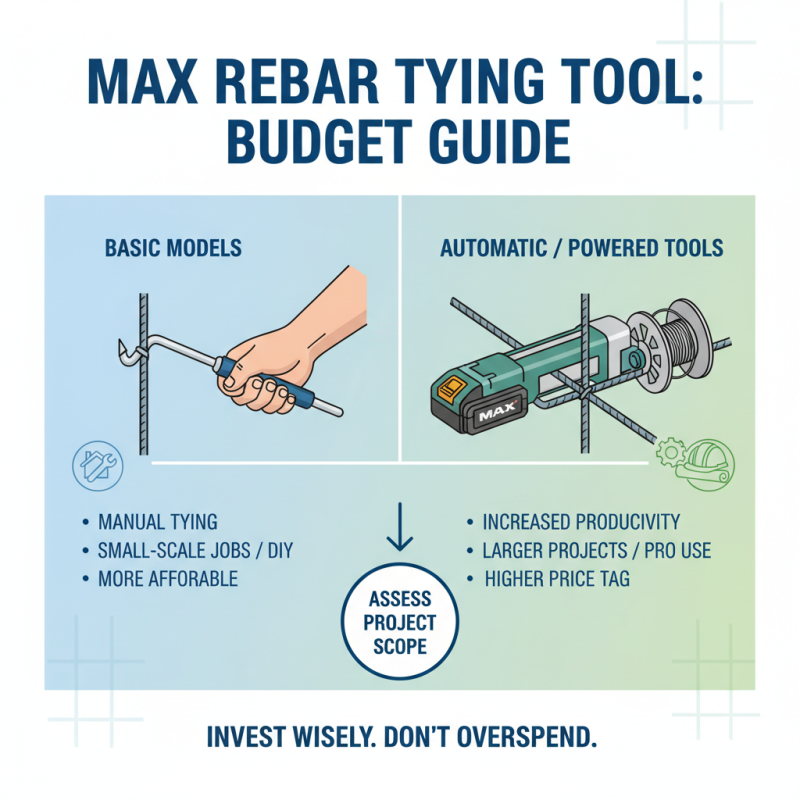

Budgeting for Your Max Rebar Tying Tool: What to Expect

When budgeting for a Max rebar tying tool, it's essential to consider the types of projects you plan to undertake. Basic models that offer manual tying capabilities are generally more affordable and suitable for small-scale jobs or DIY projects. On the other hand, automatic or powered tools, which can significantly increase productivity and reduce strain, usually come with a higher price tag. Assessing the scope of your work will help determine the necessary investment level, ensuring that you don’t overspend on features that may not be needed for your specific applications.

Additionally, factor in the long-term costs associated with maintenance and replacement parts. While a more expensive tool might seem daunting at first, its durability and efficiency could provide savings over time. It’s also wise to explore warranty options or service plans that can mitigate repair costs in the long run. By balancing initial costs with ongoing expenses, you can make an informed decision that aligns with your budget and ensures you invest in a tool that meets your project's needs efficiently.

User Reviews and Recommendations for Top Rebar Tying Tools

When selecting a rebar tying tool, user reviews can provide invaluable insight. Many professionals recommend focusing on the tool’s weight and ease of use, particularly for prolonged tasks. A lighter model can significantly reduce fatigue during large projects, while intuitive design features can enhance speed and efficiency. Users often share experiences regarding the grip and comfort of the tool, underscoring the importance of a design that minimizes strain, especially during repetitive motions.

In addition to the physical characteristics, users frequently discuss the performance and reliability of various rebar tying tools. Many emphasize the importance of a model that offers consistent tying tension, as this can greatly affect the stability of rebar structures. Recommendations often highlight tools that can accommodate different sizes of rebar, ensuring versatility for various applications. Reading through user testimonials can help prospective buyers identify which models consistently perform well in real-world conditions, guiding them towards a choice that aligns with their project requirements.

Related Posts

-

What is an Electric Rebar Tying Tool and How Does it Improve Your Efficiency

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

2025 Top 10 Max Rebar Tier Machines: Optimize Your Rebar Tying Efficiency with Industry Insights

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects

-

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs