E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

2025 How to Choose the Best Max Rebar Tying Tool for Your Projects

When embarking on construction projects, choosing the right tools can significantly impact both efficiency and quality. One of the most critical tools in the fabrication process is the Max Rebar Tying Tool. As industry expert John Smith, a leading construction engineer with over two decades of experience, aptly points out, "The effectiveness of a build starts with the right tools, and a reliable Max Rebar Tying Tool is essential for ensuring structural integrity." With various models and features available on the market today, finding the perfect Max Rebar Tying Tool tailored to your specific needs becomes a pivotal decision.

In an environment where time and precision dictate the success of a project, understanding the nuances of these tools is imperative. A Max Rebar Tying Tool not only enhances productivity but also helps maintain tight and secure ties that are essential for rebar placement in concrete structures. As we delve deeper into the selection process, it is crucial to consider factors such as tool durability, ease of use, and the specific requirements of your construction tasks. Ultimately, investing time in choosing the right Max Rebar Tying Tool can lead to significant long-term benefits for any contractor or builder.

Factors to Consider When Choosing a Max Rebar Tying Tool

When choosing the best Max rebar tying tool for your projects, several factors should be carefully considered to ensure efficiency and proper application. First and foremost, assess the tool's weight and ergonomics. A lightweight, ergonomically designed tool reduces fatigue during extended use, which is vital in large construction projects. According to industry reports, workers can save up to 20% in time and effort with models that prioritize user comfort.

Next, evaluate the power source and battery life. Tools that offer a long-lasting battery can significantly boost productivity on the job site. Opt for models featuring quick-charge technology to minimize downtime. Additionally, investigate the tying speed and capacity to ensure the tool meets the demands of your specific projects.

Tips: Always read user reviews to gauge reliability and performance. Consider investing in a tool that comes with a warranty, as this can provide peace of mind about your purchase. Moreover, if you're planning to use the tool in various environments, ensure it is robust enough to withstand different conditions while maintaining performance.

Types of Max Rebar Tying Tools Available in 2025

In 2025, there are several types of Max rebar tying tools available to meet the diverse needs of construction professionals. The manual rebar tying tools remain popular for their affordability and mechanical simplicity. These tools usually feature a trigger mechanism that allows for efficient tying without the need for electric power. They are ideal for smaller projects or for workers who prefer hands-on techniques.

On the other hand, battery-operated rebar tying tools are gaining traction due to their convenience and speed. These tools can tie multiple rebar connections quickly, making them suitable for larger construction sites where time efficiency is crucial. Their portability and rechargeable batteries allow for continuous use without being tethered to a power source.

**Tips:** When selecting a Max rebar tying tool, consider the scale and complexity of your project. For larger developments, a battery-operated tool may save substantial time. Always check the tension settings; appropriate tension ensures secure ties without damaging the rebar. Ultimately, assessing your project's requirements and the available features of each tool type will lead to the best choice for your tying needs.

2025 Max Rebar Tying Tool Performance Comparison

Evaluating the Efficiency and Speed of Rebar Tying Tools

When it comes to selecting the best max rebar tying tool for your projects, understanding the efficiency and speed of these tools is paramount. The latest advancements in technology, such as robotic arms designed to tie rebar on bridges, are a game changer in this field. These robots require minimal supervision from a single worker, significantly cutting labor hours in half and reducing the physical strain often associated with manually tying rebar. This innovation not only enhances productivity but also prioritizes worker safety by minimizing the hazards of maneuvering around heavy bundles of rebar.

Tips for choosing the right rebar tying tool include evaluating the speed of the tool in various conditions. Look for tools that offer adjustable tying speeds, allowing you to adapt to different project demands. Additionally, consider the weight and portability of the tool to ensure it fits well into your workflow without imposing excessive strain on the user. Lastly, always assess the durability and maintenance requirements of the tool, as investing in a robust option may lead to long-term savings and efficiency in your projects.

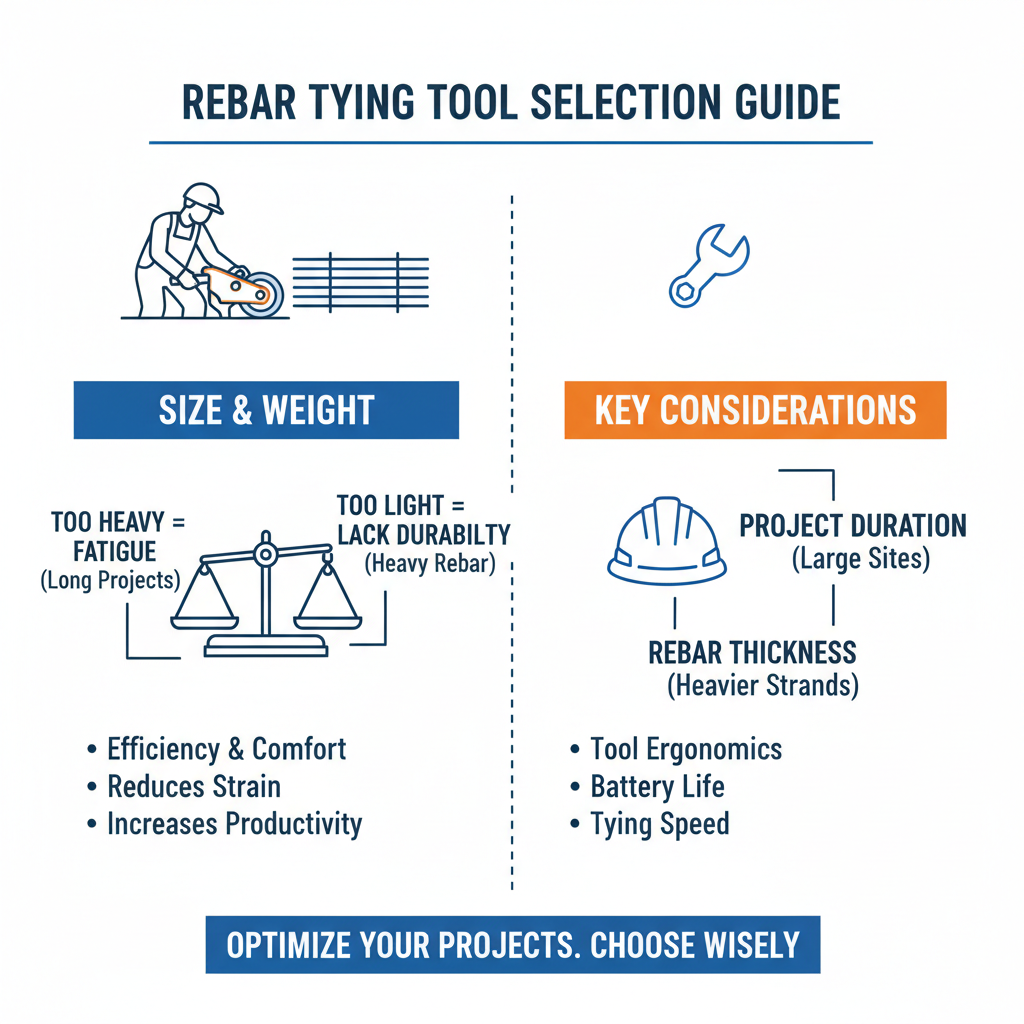

Tips for Selecting the Right Size and Weight for Your Needs

Choosing the right size and weight for a max rebar tying tool is crucial to ensure efficiency and comfort during your projects. A tool that is too heavy can lead to fatigue, particularly if you're working on a large construction site for extended periods. Conversely, a tool that is too light may not provide the durability needed for heavier strands of rebar.

When selecting a max rebar tying tool, consider the scale of your work. For large projects or frequent use, a heavier tool might be suitable for its robust performance. On the other hand, if you're working on smaller jobs or need portability, a lighter model could be more advantageous. Additionally, think about your strength and the comfort of handling the tool over long durations.

Another important tip is to check the size of the tying mechanism. A larger tying mechanism can handle bigger rebar sizes but may also add weight. Balancing these aspects can enhance your productivity and make your rebar tying tasks less strenuous. Ultimately, picking the right size and weight can make all the difference in your rebar tying efficiency.

Comparing Price and Value of Different Rebar Tying Tools

When selecting the best max rebar tying tool for your projects, it is crucial to consider both price and value. Different tools on the market range considerably in price, which can affect your budget and operational costs. While cheaper options may seem appealing, they often compromise on durability and efficiency, leading to increased long-term costs. Higher-priced tools usually come with advanced features, like automatic tying mechanisms, and often include better warranties and customer support. Therefore, it is vital to weigh these factors before making a purchase.

Tips to consider include evaluating the specific needs of your projects. If you frequently work on large-scale projects, investing in a high-quality tool will save you time and effort over time. Additionally, examine reviews and user feedback to gauge the tool's performance in real-world applications. Always take into account the cost of replacement parts and service, as they can significantly impact the overall value of the tool. By thoroughly comparing different options based on these criteria, you can find the best rebar tying tool that meets your requirements without overspending.

2025 How to Choose the Best Max Rebar Tying Tool for Your Projects - Comparing Price and Value of Different Rebar Tying Tools

| Tool Type | Price ($) | Weight (lbs) | Battery Life (hours) | Tying Speed (ties/min) | Warranty (years) |

|---|---|---|---|---|---|

| Manual Tying Tool | 25 | 2 | N/A | 20 | 1 |

| Electric Tying Tool | 150 | 5 | 3 | 40 | 2 |

| Cordless Tying Tool | 200 | 4 | 2.5 | 35 | 3 |

| Pneumatic Tying Tool | 350 | 6 | N/A | 60 | 1 |

Related Posts

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

Max Rebar Tier: Revolutionizing Rebar Tying Efficiency with 30% Faster Workflows

-

Top 5 Electric Rebar Tying Tools for Efficient and Fast Construction

-

Max Rebar Tying Tool: The Ultimate Solution for Fast and Efficient Rebar Tying

-

Top 10 Tips for Efficient Rebar Tying Techniques

-

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs