E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs

In the ever-evolving landscape of construction technology, the Automatic Rebar Tying Machine has emerged as a crucial tool for enhancing efficiency and reducing manual labor. According to Dr. Michael Harris, a renowned expert in construction automation, “Investing in an Automatic Rebar Tying Machine can significantly streamline the rebar installation process, resulting in both time and cost savings.” As construction projects become increasingly complex, the demand for effective solutions that can handle high-volume tasks with precision and speed continues to grow.

Selecting the right Automatic Rebar Tying Machine tailored to your specific construction needs is essential for maximizing productivity and ensuring safety on the job site. With numerous options available, understanding the key features and functionalities of these machines is vital for making an informed decision. Factors such as tying speed, battery life, and ease of use play a significant role in determining which machine will best serve your project's requirements. By taking the time to evaluate these elements, construction professionals can make choices that enhance their workflow, ultimately leading to successful project outcomes.

Understanding the Basics of Automatic Rebar Tying Machines

Automatic rebar tying machines are essential tools in modern construction, designed to streamline the process of tying rebar efficiently and effectively. These machines use innovative technology to automate the tying process, which significantly reduces labor time and increases safety on construction sites. By eliminating the need for manual tying, which can be both time-consuming and physically demanding, automatic rebar tying machines allow workers to focus on other critical tasks, enhancing overall productivity.

Understanding the basics of these machines involves recognizing the mechanisms that enable them to function optimally. Most automatic rebar tying machines operate with electric or battery-powered systems, which drive a wire tying mechanism that securely binds rebar intersections. Features such as adjustable settings for tension and tie strength, as well as compatibility with various rebar sizes, are crucial considerations. Additionally, the ease of operation and maintenance can greatly influence the machine's efficiency and longevity, making it vital for construction teams to choose a model that best fits their specific project needs and equipment requirements.

Key Features to Look for in a Rebar Tying Machine

When selecting an automatic rebar tying machine, several key features should be considered to ensure it meets your construction needs effectively. One of the most important aspects to evaluate is the machine's tying speed. A faster tying machine can significantly improve productivity on site, allowing workers to complete tasks efficiently. Additionally, look for the machine's tying strength, as it needs to securely fasten the rebar without compromising integrity under load conditions.

Another crucial feature to assess is the battery life or power source of the machine. A rebar tying machine with a longer battery life can reduce downtime and the need for frequent recharging, making it more practical for large-scale projects. Ergonomics should also be a priority; a lightweight design with comfortable grips helps reduce operator fatigue during extended use. Finally, consider the versatility of the machine in handling various rebar diameters and tying styles, as this flexibility can accommodate a range of construction requirements.

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs - Key Features to Look for in a Rebar Tying Machine

| Feature | Description | Importance Level | Average Price Range |

|---|---|---|---|

| Tying Speed | The speed at which the machine can tie rebar. | High | $400 - $1000 |

| Battery Life | Duration the machine can operate before needing a recharge. | Medium | $50 - $150 |

| Weight | The total weight of the machine, affecting portability. | High | N/A |

| Ease of Use | User-friendliness and setup time required. | High | N/A |

| Durability | Construction quality and ability to withstand tough conditions. | High | $500 - $1200 |

| Safety Features | Safety mechanisms to prevent accidents during operation. | Medium | N/A |

Comparative Analysis of Popular Rebar Tying Machines on the Market

When selecting the best automatic rebar tying machine, it is essential to conduct a comparative analysis of the popular models available in the market. According to a recent industry report by Technavio, the global market for rebar tying machines is expected to grow significantly, driven by the increasing demand for automation in construction processes. Key factors that differentiate these machines include tying speed, durability, and the type of wire used. Machines capable of achieving tying speeds of up to 50 ties per minute can drastically reduce labor time on construction sites, which is critical in meeting project deadlines.

Moreover, the durability and maintenance of these machines play a crucial role in their overall effectiveness. A report from Grand View Research highlights that rebar tying machines with high-quality components can withstand harsh working conditions, reducing downtime and repair costs. An analysis of user reviews and specifications shows that machines with advanced features, such as adjustable tying tension and battery longevity, tend to deliver superior performance. By evaluating these parameters, construction managers can make informed decisions that align with their specific project requirements and budget constraints, ultimately boosting efficiency and productivity on-site.

Assessing Your Construction Project's Specific Rebar Requirements

When selecting an automatic rebar tying machine, it's crucial to assess the specific rebar requirements of your construction project. Understanding factors such as the type and size of rebar, tying speed, and project scale can significantly impact efficiency and productivity. According to recent industry reports, the global market for automatic rebar tying machines is projected to grow at a CAGR of approximately 6.2% over the next five years, indicating a robust demand driven by construction projects requiring enhanced efficiency and safety.

Furthermore, analyzing your project’s rebar configuration is essential. Reports indicate that projects involving complex structures with intricate rebar layouts may benefit from machines capable of dealing with multiple rebar diameters and tying patterns. For instance, large-scale infrastructures like bridges and high-rise buildings often necessitate machines that can handle high-volume tying while maintaining consistent tension and accuracy. This alignment between the machine's capabilities and the specific demands of your project ultimately leads to optimized workflow and reduced labor costs, which can be critical in meeting project deadlines and budgets.

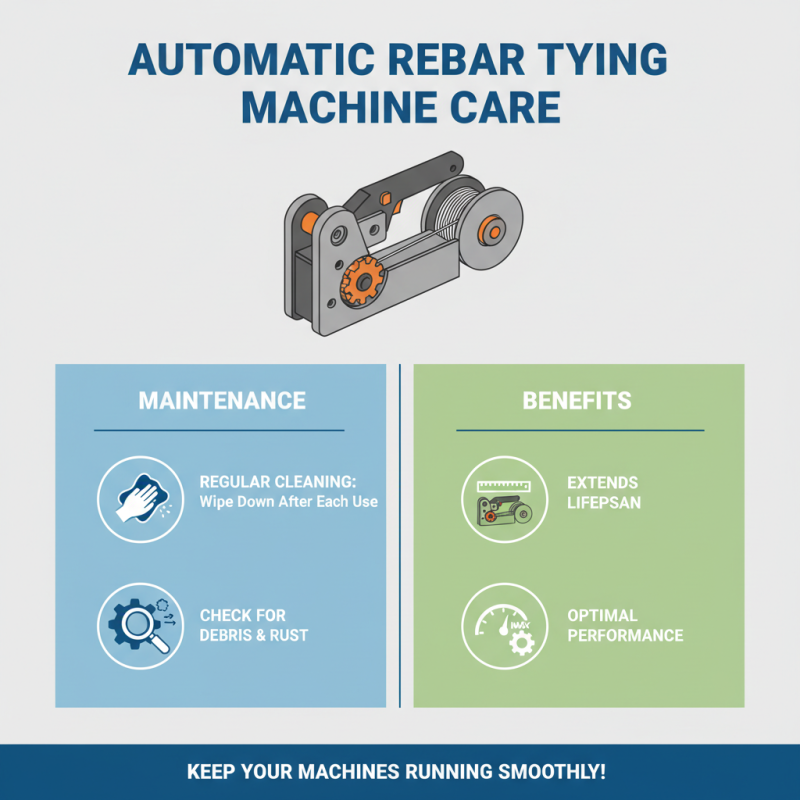

Maintenance and Care Tips for Automatic Rebar Tying Machines

When it comes to maintaining and caring for your automatic rebar tying machines, proper upkeep is essential for ensuring longevity and optimal performance. Regular cleaning should be a top priority; debris and rust can accumulate, affecting the machine's efficiency. After each use, wipe down the machine with a soft cloth and check for any leftover debris in its components. This simple step can significantly extend the lifespan of the machine.

Another important aspect of maintenance is lubrication. Ensuring that moving parts are well-lubricated will prevent wear and tear, enhancing overall functionality. Use the appropriate lubrication recommended by the manufacturer and follow guidelines for intervals between applications. Remember to inspect the battery and electrical components as well, checking for any signs of damage or corrosion that may hinder performance.

Tips for maintaining your automatic rebar tying machine include scheduling routine inspections to catch potential issues early, keeping a repair toolkit handy for minor adjustments, and storing the machine properly when not in use. Always refer to the user manual for specific maintenance instructions tailored to your machine to keep it in top operating condition. These proactive measures will ensure efficiency on the job site and provide peace of mind.

Related Posts

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

2025 Top 10 Max Rebar Tier Machines: Optimize Your Rebar Tying Efficiency with Industry Insights

-

Top 5 Electric Rebar Tying Tools for Efficient and Fast Construction

-

Max Rebar Tying Tool: The Ultimate Solution for Fast and Efficient Rebar Tying