E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

2026 Best Stand Up Rebar Tying Tool for Efficient Construction?

In the fast-paced world of construction, efficiency is key. The right tools can significantly improve productivity. Among these, the Stand Up Rebar Tying Tool stands out, offering unique advantages. This tool enhances workflow and reduces strain on workers. The design allows users to tie rebar while standing, eliminating the need for awkward positions.

Using a Stand Up Rebar Tying Tool can change how construction teams operate. No more bending over for hours. Workers can maintain their energy and focus. Nevertheless, some users report challenges with tool adjustment. It's important to find the right settings for your project. User feedback often highlights the learning curve when first using the tool. Overall, it’s a game-changer in rebar tying.

As we explore the best options for 2026, it’s vital to consider various features. Durability, portability, and ease of use all play a role. Investing in the right Stand Up Rebar Tying Tool can lead to significant long-term benefits. Let’s dive into the top choices for efficient and effective construction.

Overview of Rebar Tying Tools in Construction Industry

Rebar tying tools play a crucial role in construction. They ensure that rebar is securely fastened, which is vital for structural integrity. In recent years, the construction industry has seen a surge in the use of automated rebar tying tools. According to the Construction Industry Institute, labor productivity can improve by up to 25% with the right tools. This statistic highlights the importance of investing in quality equipment.

However, not all construction sites are equipped with advanced tying tools. Some laborers still rely on manual methods, which can lead to inconsistencies. A study published by the American Society of Civil Engineers indicates that these manual tools can generate more errors. Proper training and tool selection make a significant difference.

Tips for selecting a rebar tying tool: Consider ease of use and weight. A lightweight tool can reduce fatigue, allowing workers to perform longer. Furthermore, always evaluate the durability of the tying mechanism. Your choice can impact project timelines. Some may struggle with transitioning to automated tools. Slow adaptation can be a barrier to efficiency, reminding us of the importance of ongoing training.

Key Features to Consider for Stand Up Rebar Tying Tools

When selecting a stand-up rebar tying tool, several essential features warrant attention. The tool's weight is crucial. A lightweight design enhances mobility on job sites. It allows users to maneuver easily while working, reducing fatigue during long hours. Look for ergonomic handles. These can significantly impact comfort and control. A tool that fits well in hand boosts productivity.

Efficiency also hinges on tying speed. A tool that ties quickly saves time and labor costs. Some options allow for multiple ties in a single motion. This can cut down on repetitive tasks. Additionally, consider the tool's durability. Heavy-duty materials withstand tough conditions on construction sites. They resist wear and tear, ensuring longevity.

However, users should reflect on their specific needs. Not every design suits every project. Some tools may feel cumbersome in smaller spaces. Testing different models can help identify the best fit. Balancing efficiency with usability is vital. A tool that feels clunky could hinder progress. Overall, the right features align with the user's unique workflows.

2026 Best Stand Up Rebar Tying Tool Performance Comparison

This chart compares the tying speed of various stand up rebar tying tools measured in ties per hour. It highlights the efficiency of each tool, helping contractors and construction firms to make informed decisions based on performance metrics.

Top Brands and Models for 2026 Stand Up Rebar Tying Tools

The construction industry is evolving rapidly, and 2026 will showcase various stand-up rebar tying tools. Choosing the right tools can significantly boost productivity on-site. Reports indicate that efficient rebar tying methods can enhance overall project timelines by 20%. Understanding key features in the latest models becomes essential for contractors.

When browsing options, pay attention to ergonomics. Tools designed to reduce physical strain can lead to fewer worker injuries. In fact, data shows that ergonomic tools can decrease workplace injuries by up to 30%. Comfort in design improves work efficiency. However, not every model is suitable for every project. Each job has unique needs that must be considered.

Tip: Consider testing tools before purchase. Manufacturers often provide trials. This helps evaluate comfort and performance. Always prioritize tools that reduce repetitive stress, enhancing overall productivity. Additionally, check for user reviews and feedback. These insights can guide your decision-making process.

Comparison of Manual vs. Stand Up Rebar Tying Tools

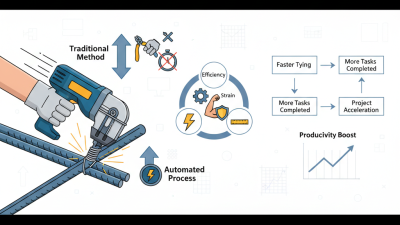

When it comes to rebar tying tools, two options stand out: manual tools and stand up tools. Manual rebar tying requires skill and precision. Workers twist wire by hand, which can be exhausting. Many find it tedious, especially on large projects. It’s not always efficient. Fatigue can lead to mistakes. The process can slow down work significantly.

Stand up rebar tying tools change the game. They allow workers to tie rebar without bending over. This can save time and reduce strain on the body. However, they might not work well in tight spaces. Not all workers feel comfortable with this technology at first. There’s a learning curve, and some might struggle initially. Efficiency can diminish if misused.

The choice between these tools often depends on the project's needs. Manual tying can still shine in smaller or intricate setups. On the other hand, larger sites benefit from stand-up tools for speed. Ultimately, assessing your project and crew's expertise is vital. Each method holds value, yet both require reflection on productivity and comfort.

Benefits of Using Efficient Rebar Tying Tools in Construction

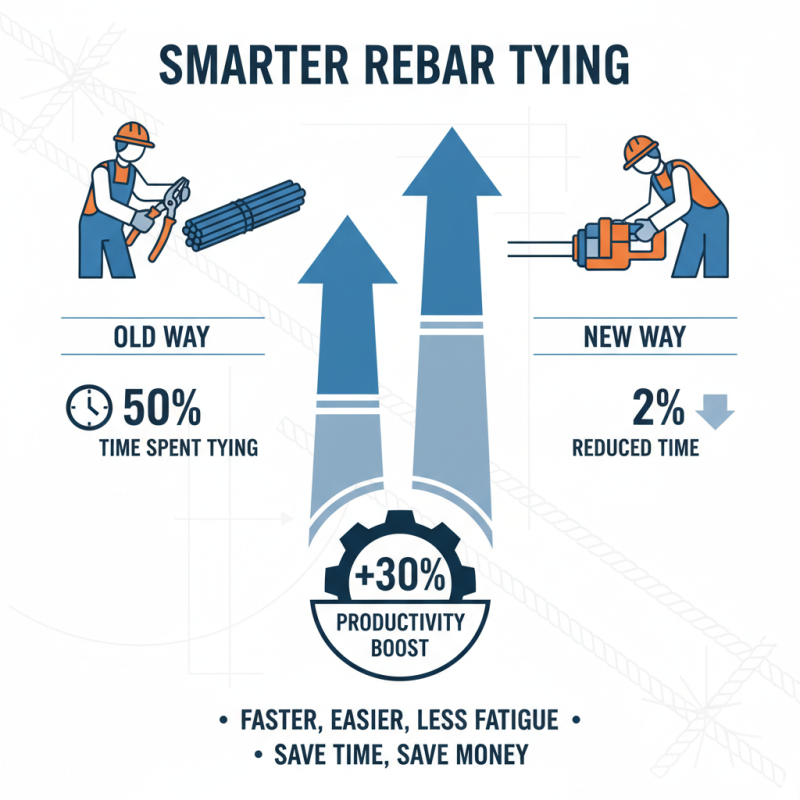

Efficient rebar tying tools can dramatically enhance construction processes. In a recent industry report, it was highlighted that efficient tools can improve productivity by up to 30%. These tools simplify the repetitive task of tying rebar, which can otherwise be monotonous and time-consuming. A construction worker might spend up to 50% of their time just tying rebar. With better tools, this percentage can be significantly reduced.

Additionally, using quality rebar tying tools can improve safety on site. Workers are less likely to sustain injuries caused by repetitive motions. An analysis indicated a 20% decrease in worker injuries when efficient tools were utilized. However, many companies hesitate to upgrade. They worry about the initial cost without recognizing long-term benefits.

While efficient tools offer clear advantages, not all teams fully adapt to their use. Some still rely on outdated practices. This reluctance can stem from a lack of training or familiarity. Investing in employee education on new tools could bridge this gap. Embracing change can lead to enhanced productivity and safety in the long run. Ignoring these advancements may hinder progress.

Related Posts

-

What is an Electric Rebar Tying Tool and How Does it Improve Your Efficiency

-

How to Choose the Best Rebar Tying Tool for Your Construction Projects

-

How to Choose the Best Max Rebar Tying Tool for Your Project

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

Revolutionizing Construction: How Stand Up Rebar Tying Tools Enhance Efficiency and Safety

-

The Ultimate Guide to Boosting Construction Efficiency with a Stand Up Rebar Tying Machine