E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

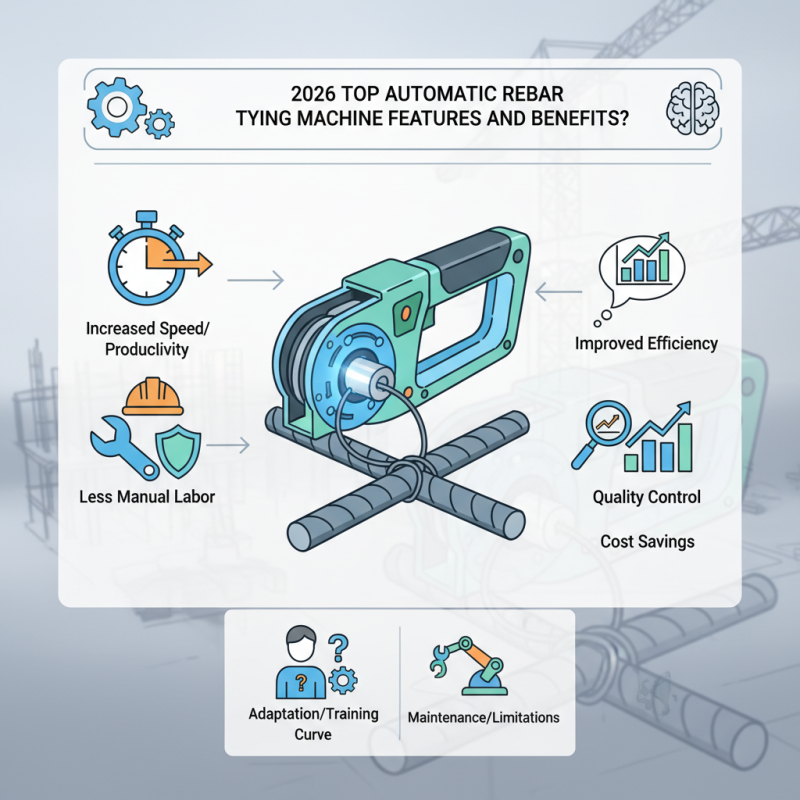

2026 Top Automatic Rebar Tying Machine Features and Benefits?

The construction industry constantly seeks innovation. One standout tool is the Automatic Rebar Tying Machine. This machine simplifies tasks that were once labor-intensive and time-consuming. As construction projects grow more complex, the demand for efficiency increases.

Automatic Rebar Tying Machines offer distinct features and benefits. They enhance productivity by speeding up the tying process. With automation, workers can focus on other critical tasks. However, some operators find it challenging to adapt to new technology. Training is essential to maximize the machine's potential.

Despite its advantages, the Automatic Rebar Tying Machine is not perfect. Some models may struggle with tight spaces or specific angles. Regular maintenance is necessary to ensure optimal performance. Ultimately, understanding both strengths and limitations can lead to better decision-making in construction projects.

Key Features of the 2026 Top Automatic Rebar Tying Machines

The 2026 top automatic rebar tying machines come with several remarkable features. Efficiency has been a focus for these machines. They can tie rebar quickly without sacrificing quality. A well-designed mechanism allows for precise ties every time. A typical cycle time is under 2 seconds. This speed can significantly improve productivity on construction sites.

User-friendliness is another key point. These machines often have an intuitive interface. Operators can easily learn the controls. They feature lightweight designs, enhancing portability. Battery-operated models also provide flexibility in various working conditions. However, some users may find battery life inconsistent. Regular checks and maintenance can help prevent downtime.

Safety features are crucial. Many machines include automatic shut-off systems. This prevents accidents and protects workers. Nonetheless, operators must remain vigilant. Training sessions should emphasize safe practices. The technology is impressive, but human oversight is vital. Overall, these machines represent a leap in construction efficiency. Yet, careful handling and ongoing training remain essential.

Advantages of Using Automatic Rebar Tying Machines in Construction

Automatic rebar tying machines offer significant advantages in construction projects. These tools enhance efficiency and reduce manual labor. According to industry reports, automating this process can increase productivity by up to 50%. Workers spend less time tying rebar manually, which accelerates project timelines tremendously.

Construction sites often face challenges, such as worker safety and consistency in tying methods. Automatic machines reduce the risk of repetitive strain injuries, a common issue in manual tying. However, reliance on equipment may lead to skill atrophy among workers. Training remains essential, and operators must understand how to use the machines effectively.

Additionally, precision is a critical factor. Machines can produce uniform ties, resulting in stronger structures. Yet, if a machine malfunctions, it can slow down the entire operation. Regular maintenance and staff training are crucial to avoid such pitfalls. Overall, while the advantages are significant, a balanced approach is necessary to maximize value while addressing potential shortcomings.

Comparison of Different Models of Automatic Rebar Tying Machines

When exploring automatic rebar tying machines, it’s essential to compare the different models available. Each machine offers unique features that can impact efficiency and functionality on the job site. Some machines are lightweight, making them easier to handle. Others have advanced tying mechanisms, which can save time during installation.

One model may have a higher tying speed, allowing workers to complete tasks quickly. However, this speed can sometimes lead to inaccuracies. It’s crucial to assess the balance between speed and precision. Another model may focus on battery life. A longer-lasting battery can enhance productivity, but increased weight might be a drawback.

Different machines also offer varying levels of user comfort. Handgrip design and weight distribution can affect how easily an operator uses the machine. Users often report fatigue from prolonged use. Finding the right fit is important. Each project may require different features. Some machines cater to specific job sizes, while others excel in versatility. The choice ultimately depends on the user's unique needs and preferences, reflecting the importance of firsthand experience and feedback.

Technological Innovations in 2026 Rebar Tying Machine Designs

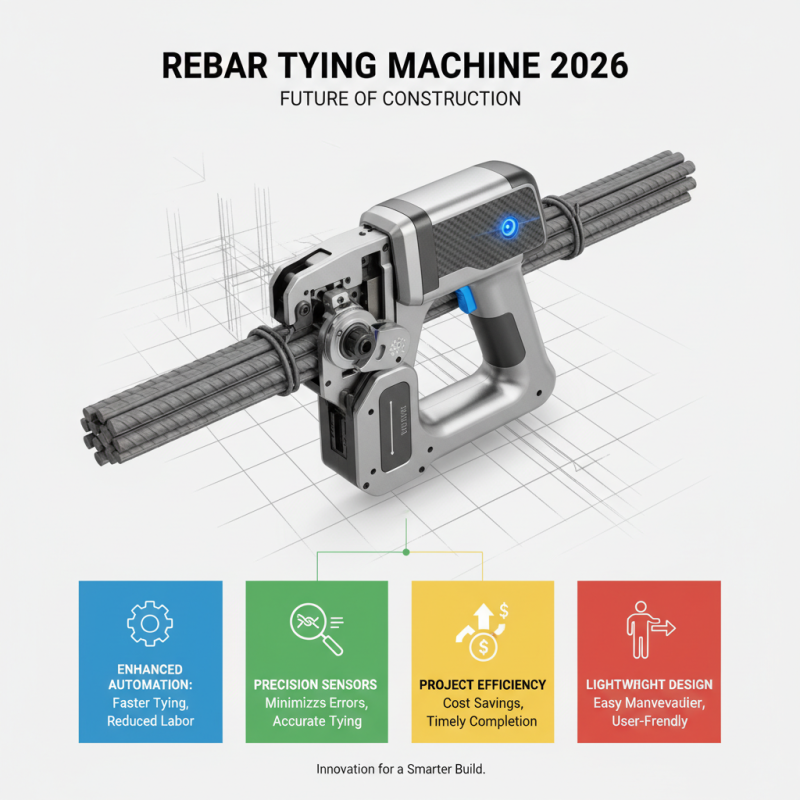

The rebar tying machine in 2026 showcases remarkable technological innovations. Enhanced automation features streamline the tying process, reducing labor costs significantly. These machines now integrate advanced sensors for precise tying, minimizing errors and improving project efficiency. The lightweight design allows easy maneuverability on construction sites, making them user-friendly.

These machines also feature smart connectivity options, enabling real-time data tracking. Users can monitor performance metrics and maintenance alerts remotely. This connectivity leads to better decision-making and operational efficiency. However, the fast-paced development of these technologies may outpace user training, creating potential adaptation challenges. Safety protocols must also evolve alongside these innovations to prevent accidents during operation.

Incorporating lightweight materials into the design has made these machines easier to transport. Yet, there is ongoing debate about their durability compared to traditional models. Some field workers express concerns about performance under heavy use. Balancing innovation with practicality remains an essential discussion in the industry.

Maintenance Tips for Optimizing Rebar Tying Machine Performance

Proper maintenance is essential for your automatic rebar tying machine to perform optimally. Regularly checking the machine's components can help prevent issues. Dirt and debris can affect functionality. Clean the machine after use. A simple wipe-down can make a significant difference.

In addition, lubricate moving parts regularly. This ensures smooth operation and reduces wear and tear. Make sure to use the correct type of lubricant. Over-lubrication can cause buildup, which may lead to malfunctions.

Lastly, keep an eye on tension settings. Incorrect tension can lead to weak ties. Adjust settings based on the specifications of the rebar being used. Periodic checks can help maintain consistency. These small, often overlooked steps can enhance the lifespan of your machine. They might seem insignificant, but they have a big impact.

2026 Top Automatic Rebar Tying Machine Performance Metrics

This chart illustrates the key performance metrics of top automatic rebar tying machines for 2026. The metrics include speed, weight, cost, maintenance frequency, and power consumption, all of which are crucial for optimizing performance and operational efficiency.

Related Posts

-

What is an Electric Rebar Tying Machine and How Does It Improve Efficiency?

-

Top 10 Max Rebar Tier Guns for Efficient Construction Projects

-

Top Electric Rebar Tying Tools of 2025: What to Look For

-

Essential Guide to Tie Wire Guns: Benefits, Uses, and Buying Tips

-

How to Choose the Best Automatic Rebar Tying Machine for Your Construction Needs

-

Revolutionizing Construction: How Electric Rebar Tying Machines Boost Productivity by 50% in Modern Projects